Submit feedback

Custom Polyester Ammonia Knitted Elastic Fabric For Swimwear

-

APS038301 32G polyester ammonia matte swimsuit fabric

-

APS038302 Warp knitted 32G polyester matte underwear fabric for women

-

APS0383 36G needle warp knitted polyester ammonia matte corset fabric

-

APS0383P 36 needle warp knitted polyester ammonia matte corset fabric

-

190GSM 45D warp knitted polyester matte plain cloth swimsuit underwear fabric

About Us

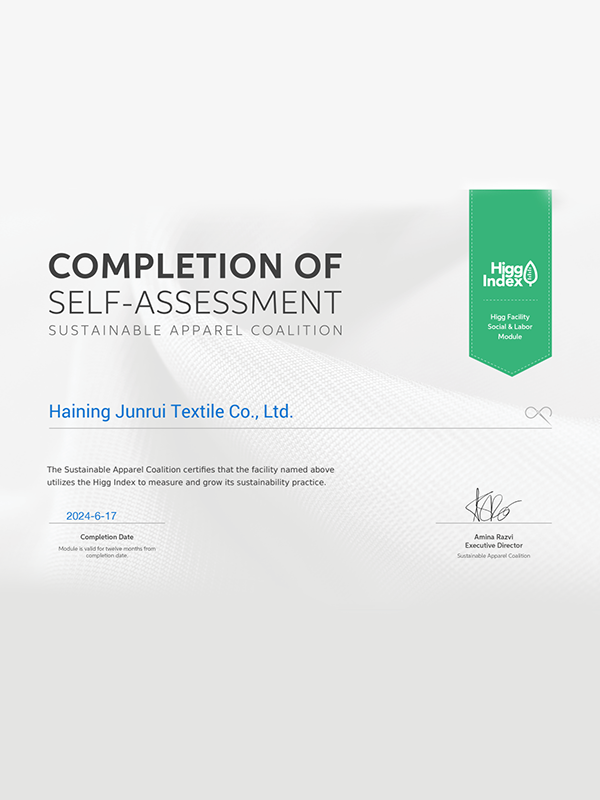

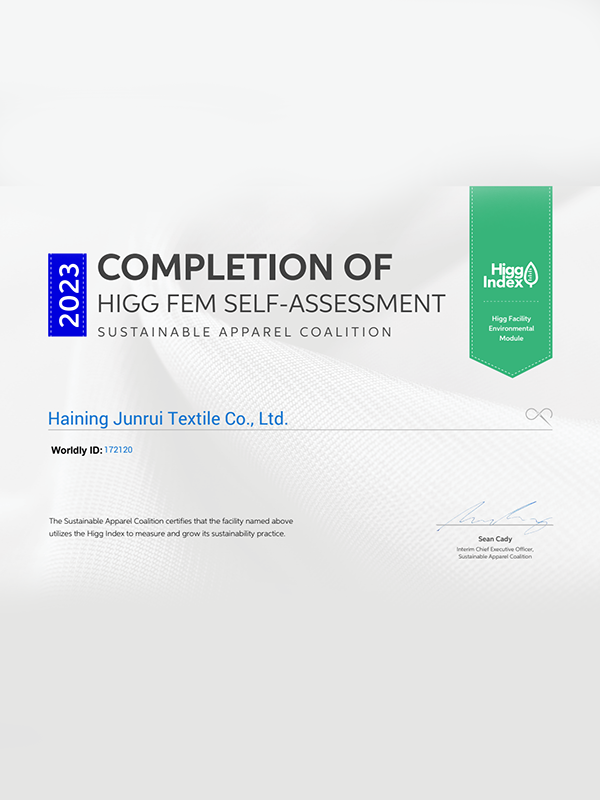

Haining Junrui Textile Co., Ltd. is a branch of Taiwan Artron Industrial Co., LTD. Since 1991→ Artron Dyeing & Weaving Co., Ltd. was established in 2000 → Yayun Trading Co., Ltd. was established in 2014 → Haining Jungrui Textile Co., Ltd. was established in 2022. Haining Jungrui Textile Co., Ltd. has more than 30 years of production and sales experience in the textile field.

As a China Custom Polyester Ammonia Knitted Elastic Fabric For Swimwear Manufacturers and Polyester Ammonia Knitted Elastic Fabric For Swimwear Manufacturers, we are committed to the production of high-quality fabrics, to provide customers with high-quality service, products are exported to the United States, Europe, Japan, Australia, Southeast Asia, and other countries and regions.

News

-

Industry News 2026-02-05

Warp knitting fabrics have become an essential component in various industries, ranging from fashion to industrial applications. With their unique structure and qualities, they offer distinct advantages over other types ...

View More -

Industry News 2026-01-29

Introduction to Tricot Fabric Tricot fabric, known for its unique structure and versatile applications, has become a popular choice in the garment industry. Made from a knit structure, this fabric is widely used for prod...

View More -

Industry News 2026-01-22

Introduction Sportswear has evolved from basic functionality to a vital component of modern athletic performance. The fabric used in sportswear plays an essential role in determining comfort, durability, and overall perf...

View More

Polyester Ammonia Knitted Elastic Fabric KNOWLEDGE

In the weaving process of polyester ammonia knitted elastic fabric for swimwear, what key process parameters need to be controlled? For example, how are the warp let-off amount, draft density, etc. set? What impact do these parameters have on fabric performance?

1. Control of warp let-off amount

The warp let-off amount refers to the amount or speed at which the warp yarn is fed into the loom during the weaving process. In the weaving of polyester-spandex knitted stretch swimwear fabric, the control of the warp let-off amount is particularly critical because it directly affects the elasticity and stability of the fabric.

Setting of warp let-off amount:

For polyester-spandex knitted stretch fabric, the setting of the warp let-off amount needs to be more refined due to the addition of spandex yarn. Spandex yarn has good elasticity, but excessive stretching will cause the fabric to lose its original elasticity and stability. Therefore, when setting the warp let-off amount, the elastic properties of spandex yarn must be fully considered.

JUNRUI uses an advanced warp let-off system that can accurately control the warp let-off amount to ensure uniform feeding of the warp yarn during the weaving process. At the same time, the company also makes personalized adjustments to the warp let-off amount according to the specifications of the fabric and the specific needs of the customer.

The influence of warp feed on fabric performance:

If the warp feed is too large, the fabric will be overstretched, reducing the elasticity and stability of the fabric, affecting the comfort and service life of wearing.

If the warp feed is too small, the fabric will be tight, increasing the difficulty of weaving, and the fabric will be prone to creases and cracks.

A reasonable warp feed setting can ensure that the fabric has stable size and shape while maintaining good elasticity, meeting the high requirements of swimwear fabrics for elasticity and stability.

2. Control of pulling density

The pulling density refers to the degree of stretching of the fabric by the pulling device during the weaving process, which directly affects the tightness and elasticity of the fabric.

Setting of pulling density:

The setting of pulling density needs to be adjusted according to the specifications and uses of the fabric. For polyester-spandex knitted stretch swimwear fabrics, the pulling density should be moderate to ensure that the fabric has both sufficient tightness and good elasticity.

JUNRUI uses advanced pulling devices and control systems to accurately control the pulling density. The company also makes personalized adjustments to the pulling density according to the characteristics of the fabric and the specific needs of customers to meet the needs of swimwear fabrics in different markets.

Effect of pulling density on fabric performance:

If the pulling density is too high, the fabric will be too tight, reducing the breathability and wearing comfort of the fabric. Excessive pulling will also cause stress concentration in the fabric, increasing the risk of fabric damage.

If the pulling density is too low, the fabric will be too loose, reducing the elasticity and stability of the fabric. In addition, too low a pulling density will also affect the appearance and feel of the fabric.

A reasonable pulling density setting can ensure that the fabric has good breathability and wearing comfort while maintaining tightness and elasticity. This is crucial for swimsuit fabrics, because swimsuits need to fit the skin for a long time, and have high requirements for the comfort and stability of the fabric.

3. Control of other key process parameters

In addition to the warp feed and pulling density, in the weaving process of polyester-spandex knitted stretch swimsuit fabrics, it is also necessary to control several other key process parameters, such as knitting density, yarn tension, etc.

Knitting density: Knitting density refers to the number of coils per unit length. It directly affects the thickness, tightness and elasticity of the fabric. JUNRUI uses advanced knitting equipment and technology to accurately control the knitting density, ensuring that the fabric has good breathability and comfort while maintaining elasticity and stability.

Yarn tension: Yarn tension refers to the tensile force exerted on the yarn during the weaving process. It directly affects the flatness and uniformity of the fabric. JUNRUI uses a precise tension control system to ensure that the yarn maintains a stable tension during the weaving process, thereby producing a flat and uniform fabric.

4. JUNRUI's technical advantages

In the weaving process of polyester-spandex knitted stretch swimwear fabric, JUNRUI relies on the following technical advantages to ensure the high quality of the product:

Advanced production equipment: The company introduces internationally advanced knitting equipment and dyeing and finishing equipment to ensure precise control and efficient operation of the production process.

Optimized production process: The company optimizes the production process, shortens the delivery cycle, improves production efficiency, and ensures product quality.

Strict quality control: The company carefully supervises every link from raw material procurement to production process to ensure that the products meet international standards and customer-specific needs.

Personalized customization service: The company can provide personalized customization services according to the specific needs of customers and create differentiated products to meet their special market positioning and customer groups.

English

English 中文简体

中文简体 Español

Español 日本語

日本語