Submit feedback

Custom High Stretch Brocade Fabric For Swimwear

About Us

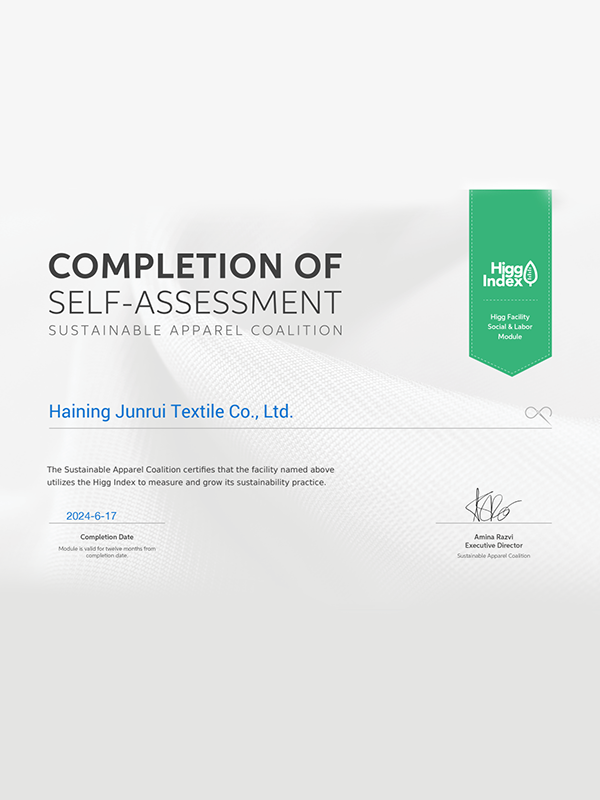

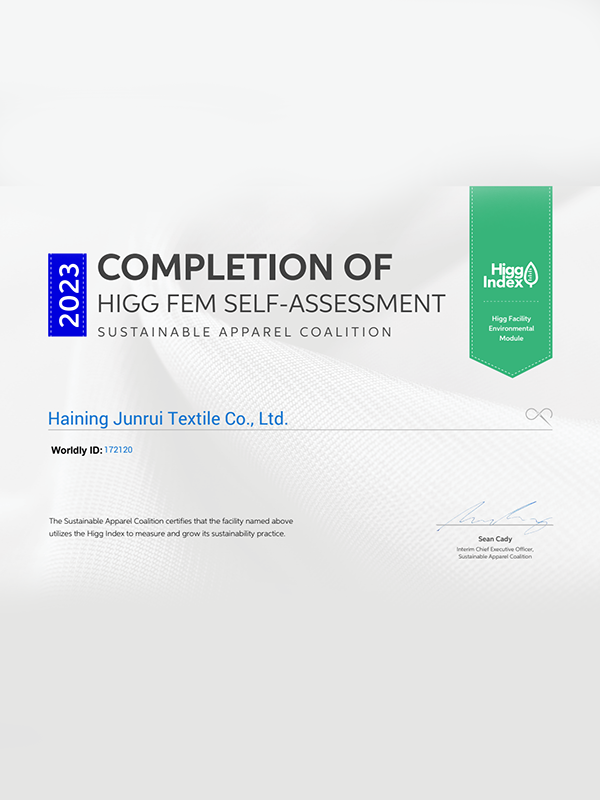

Haining Junrui Textile Co., Ltd. is a branch of Taiwan Artron Industrial Co., LTD. Since 1991→ Artron Dyeing & Weaving Co., Ltd. was established in 2000 → Yayun Trading Co., Ltd. was established in 2014 → Haining Jungrui Textile Co., Ltd. was established in 2022. Haining Jungrui Textile Co., Ltd. has more than 30 years of production and sales experience in the textile field.

As a China Custom High Stretch Brocade Fabric For Swimwear Manufacturers and High Stretch Brocade Fabric For Swimwear Manufacturers, we are committed to the production of high-quality fabrics, to provide customers with high-quality service, products are exported to the United States, Europe, Japan, Australia, Southeast Asia, and other countries and regions.

News

-

Industry News 2026-02-05

Warp knitting fabrics have become an essential component in various industries, ranging from fashion to industrial applications. With their unique structure and qualities, they offer distinct advantages over other types ...

View More -

Industry News 2026-01-29

Introduction to Tricot Fabric Tricot fabric, known for its unique structure and versatile applications, has become a popular choice in the garment industry. Made from a knit structure, this fabric is widely used for prod...

View More -

Industry News 2026-01-22

Introduction Sportswear has evolved from basic functionality to a vital component of modern athletic performance. The fabric used in sportswear plays an essential role in determining comfort, durability, and overall perf...

View More

High Stretch Brocade Fabric KNOWLEDGE

How to ensure the brightness and durability of the color during the dyeing process of high stretch brocade fabric for swimwear? Were special dyeing techniques used?

The basis for ensuring color quality from the source is the selection of high-quality environmentally friendly raw materials and dyes. JUNRUI cooperates with leading international dye suppliers to select dyes that are strictly certified, non-toxic, low-pollution and environmentally friendly. These dyes not only have high color saturation and strong color fastness, but also can significantly reduce water and air pollution during the production process. In particular, we prefer to use dyes that are easily biodegradable, minimizing the burden on the natural environment even at the final wastewater treatment stage.

In the dyeing process of high-elastic brocade swimsuit fabrics, we use advanced "low-temperature and high-pressure dyeing technology." Compared with traditional high-temperature dyeing methods, this technology can achieve effective penetration and color fixation of dyes at lower temperatures, thus greatly reducing energy consumption and carbon emissions. Low-temperature treatment helps protect the original elasticity and strength of the fabric, ensuring that the swimwear fabric can still maintain excellent shape memory and wearing comfort after multiple wears and washings.

To ensure the durability of the color, we also perform a double fixation process after dyeing. The first step is chemical fixation, which uses specific chemical additives to form a stronger bond between the dye molecules and fiber molecules to improve color fastness. The second step is to use physical fixation technology, such as ultrasonic or microwave treatment, to further promote the uniform distribution and fixation of dyes inside the fiber and enhance color stability. This dual color-fixing strategy can effectively prevent color fading and keep swimwear fabrics as bright as ever, even after prolonged exposure to the sun, seawater immersion or chlorine water environments.

During the entire dyeing process, we have also incorporated a number of environmentally friendly and energy-saving production processes. For example, a closed-loop water circulation system is used to efficiently recycle, purify and reuse the water resources used in the dyeing process, greatly reducing the consumption of fresh water and wastewater discharge. By accurately controlling dyeing time and temperature, combined with an intelligent management system, energy usage is optimized, reducing overall production costs and improving production efficiency.

At JUNRUI, quality is our lifeline. From the procurement of raw materials to the delivery of final products, every step has undergone strict screening and inspection. For high stretch brocade fabric for swimwears, we have established long-term and stable cooperative relationships with certified high-quality suppliers to ensure that all raw materials meet the highest international quality standards. After dyeing is completed, each piece of fabric will undergo multi-dimensional quality inspections such as color fastness testing, elastic recovery testing, and abrasion resistance testing. Only those products that pass strict controls at all levels will be allowed to enter the market and provide customers with Reliable quality assurance.

In addition to continuous technological innovation and environmental protection practices, JUNRUI also has a design team that keeps up with international fashion trends. They combine cutting-edge design concepts with environmental protection concepts, and cleverly integrate inspiration into the design of swimwear fabrics, which not only meets customers' needs for color brightness and durability, but also provides unique visual enjoyment and user experience. Whether it is consumers who pursue fashion trends or professional customers who require complex customized services, we can provide personalized and high-quality swimwear fabric solutions with our professional design capabilities and efficient production and delivery capabilities.

English

English 中文简体

中文简体 Español

Español 日本語

日本語