Submit feedback

Wholesale Single Side Sportswear Fabric

-

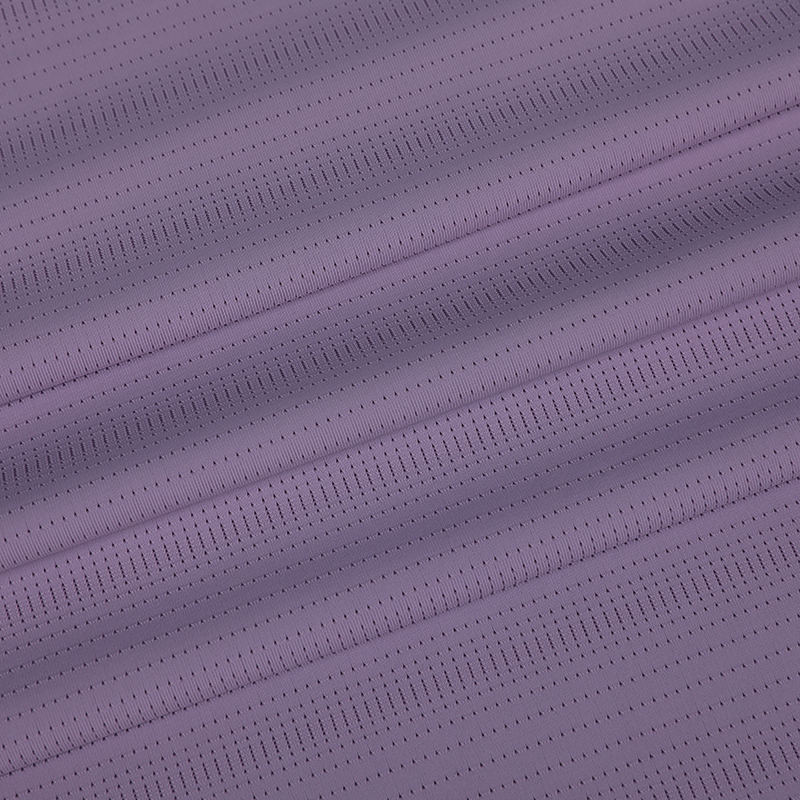

BPJ1381 Purple Rubik's Cube breathable point polyester ammonia sportswear fabric

-

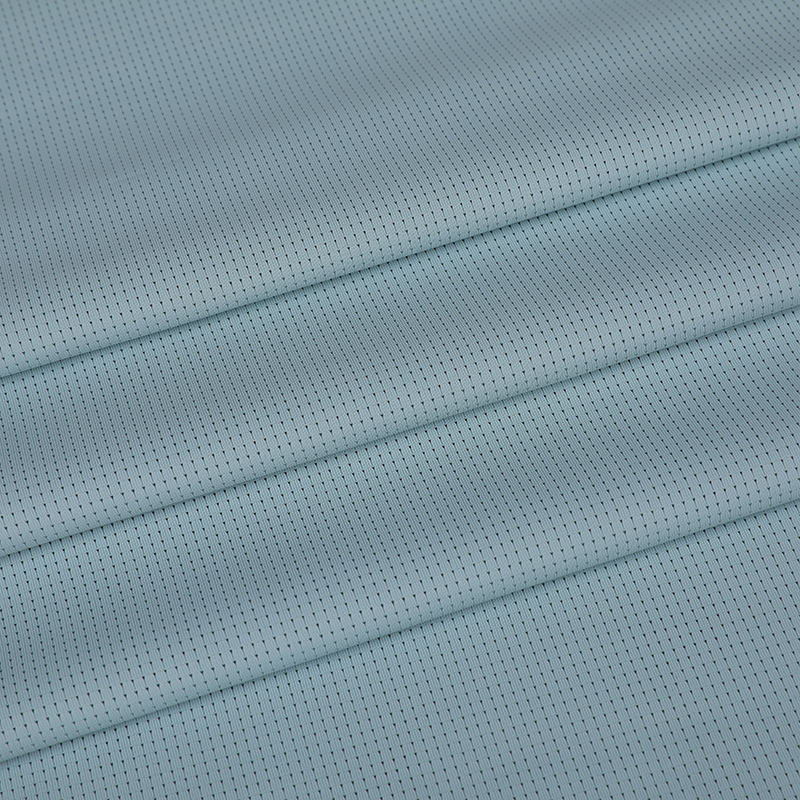

BPP1753 Polyester elastic waffle jacquard sports fabric

-

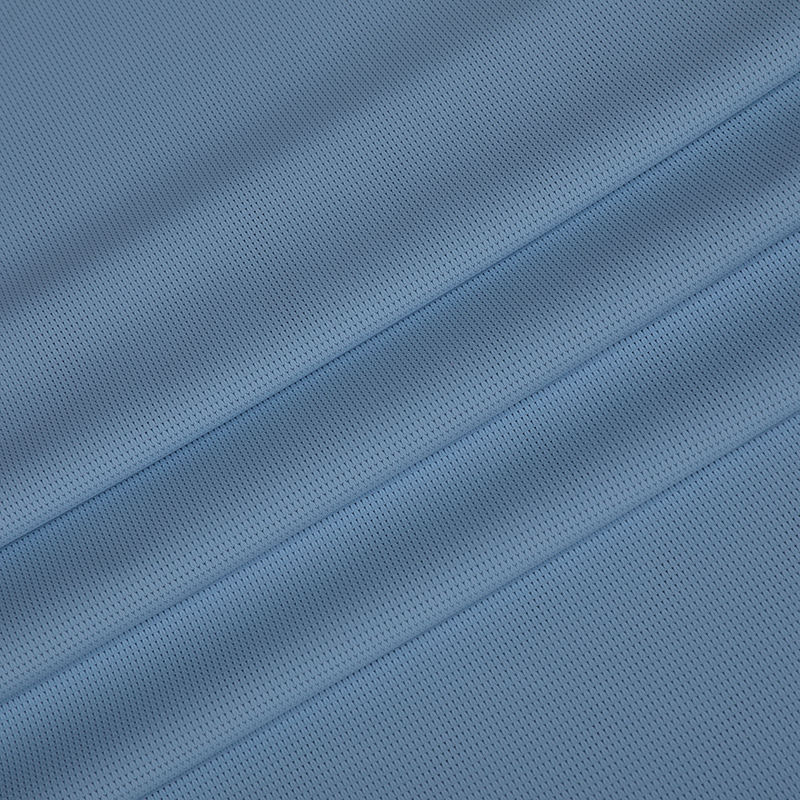

BPS1775 5030 single side ammonia T-shirt pajamas fabric

-

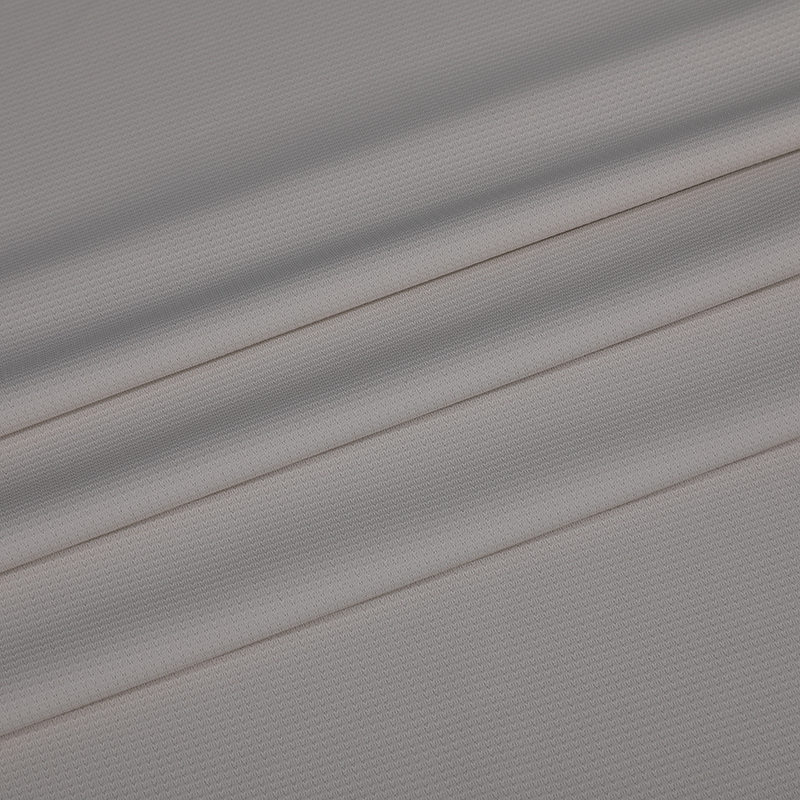

BPS110 Brocade polyester single side fabric sports shirt

-

BPJ1907 Brocade ammonia bollinger cloth polo shirt fabric

-

5020 Single side brocade ammonia cloth T-shirt underwear fabric

-

BPJ1905 Brocade ammonia small Rubik's cube jacquard cloth polo shirt sports fabric

-

BPS1823 Ice double tower polyester ammonia sports jersey fabric

-

BPS1776 5040 single side sun protective clothing fabric

-

BPJ1906 Jin ammonia eyelet jacquard sports T-shirt clothing fabric

-

BPS1825 Dynamic anta polyester ammonia sportswear fabric

-

BPJ1908 Brocade ammonia meteor hole jacquard sports Polo shirt fabric

Our range of sportswear, including cycling, running and basketball wear, is made of quality fabrics. With moisture absorption, perspiration and breathability, you can always stay dry and comfortable during exercise.

Rich and varied materials to meet different needs. Spring clothes are light and breathable, bringing fresh vitality; Summer clothes cool and quick dry, against the heat; Autumn clothing warm moderate, windproof and comfortable; Winter clothing is thick, warm and breathable.

The style is different in four seasons, and the design is intimate, without any cumbersome feeling. Whether you are cycling, running or playing basketball, you can find the one that suits you and enjoy the sport.

About Us

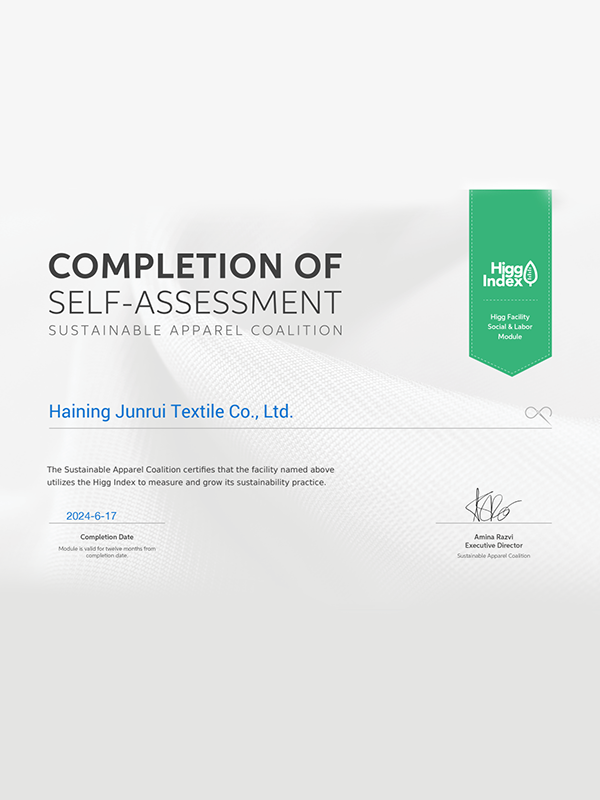

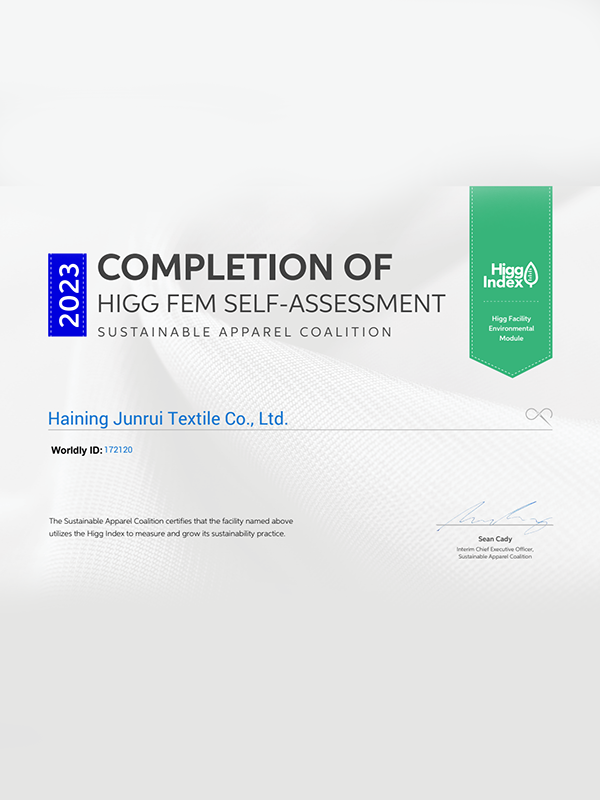

Haining Junrui Textile Co., Ltd. is a branch of Taiwan Artron Industrial Co., LTD. Since 1991→ Artron Dyeing & Weaving Co., Ltd. was established in 2000 → Yayun Trading Co., Ltd. was established in 2014 → Haining Jungrui Textile Co., Ltd. was established in 2022. Haining Jungrui Textile Co., Ltd. has more than 30 years of production and sales experience in the textile field.

As a China Wholesale Single Side Sportswear Fabric Suppliers and Jacquard Sports Fabric Company, we are committed to the production of high-quality fabrics, to provide customers with high-quality service, products are exported to the United States, Europe, Japan, Australia, Southeast Asia, and other countries and regions.

News

-

Industry News 2026-02-05

Warp knitting fabrics have become an essential component in various industries, ranging from fashion to industrial applications. With their unique structure and qualities, they offer distinct advantages over other types ...

View More -

Industry News 2026-01-29

Introduction to Tricot Fabric Tricot fabric, known for its unique structure and versatile applications, has become a popular choice in the garment industry. Made from a knit structure, this fabric is widely used for prod...

View More -

Industry News 2026-01-22

Introduction Sportswear has evolved from basic functionality to a vital component of modern athletic performance. The fabric used in sportswear plays an essential role in determining comfort, durability, and overall perf...

View More

Sportswear Fabric KNOWLEDGE

What finishing processes are required after the weaving of single-sided jacquard sportswear fabrics? How do these processes ensure the quality and appearance of the fabrics?

The desizing process is carried out. During the weaving process, sizing is usually applied to the yarn to enhance the strength and wear resistance of the yarn. However, these sizing agents may affect the comfort and hygroscopicity of the fabric in the final application. We use advanced desizing equipment and environmentally friendly desizing agents to effectively remove the sizing residue on the fabric through high temperature and high pressure treatment, while avoiding damage to the fabric fibers. This process ensures that the fabric is soft and comfortable, laying a good foundation for subsequent processing.

Next is the tentering and shaping process. Single-sided jacquard fabrics may have inconsistent widths due to uneven tension during the weaving process, affecting the efficiency of cutting and sewing. We use advanced tentering and shaping machines to shape the fabric by precisely controlling the temperature and tension. This step not only ensures the stability of the fabric width, but also improves the dimensional stability of the fabric, making it less likely to deform during subsequent processing and use.

In order to prevent the fabric from shrinking after washing, we perform pre-shrinking. Through mechanical pre-shrinking or chemical pre-shrinking methods, the shrinkage process of the fabric after multiple washings is simulated, so as to "lock" the size of the fabric in advance. This process significantly improves the dimensional stability of the fabric and ensures the fit and aesthetics of the finished garment.

For some single-sided jacquard fabrics that need to increase warmth and touch, we will perform sanding or raising. Through a professional sanding machine or raising machine, the surface of the fabric is slightly sanded or combed to form a fine fluff layer. This process not only enhances the warmth of the fabric, but also gives the fabric a softer and more comfortable touch, improving the wearing experience.

Dyeing and printing are crucial links in the finishing of single-sided jacquard fabrics. We have advanced dyeing and printing equipment, using environmentally friendly dyes and printing pastes to ensure bright colors, clear patterns and long-lasting non-fading. During the dyeing process, we strictly control parameters such as temperature, time and pH value to ensure uniform color; during the printing process, we use high-precision digital printing technology to achieve accurate restoration of complex patterns to meet the market's demand for personalized and differentiated fabrics.

In order to meet the market's demand for functional fabrics, we will also perform functional finishing on the fabrics. The addition of functions such as waterproof, windproof, breathable, antibacterial, and anti-ultraviolet are all achieved by forming micro-nano structures on the surface or inside of the fabric through specific functional finishing agents. These functional finishing agents are strictly screened and tested to ensure their safety and environmental protection. Through functional finishing, single-sided jacquard fabrics not only have basic wearing performance, but also have more added value, meeting the needs of different consumer groups.

All fabrics that have been finished will undergo strict quality inspection. We use advanced testing equipment and methods to test key indicators such as color fastness, shrinkage, tear strength, and abrasion resistance of fabrics to ensure that each batch of fabrics meets international standards and customer requirements. After passing the inspection, the fabrics will be carefully packaged and labeled for traceability and management.

English

English 中文简体

中文简体 Español

Español 日本語

日本語