Submit feedback

Custom All Polyester Jacquard Fabric For Fashion Clothing

About Us

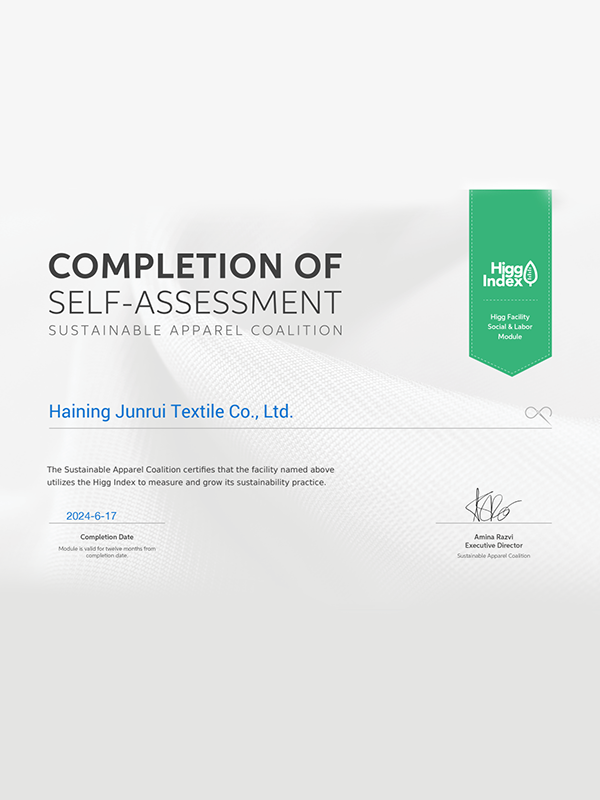

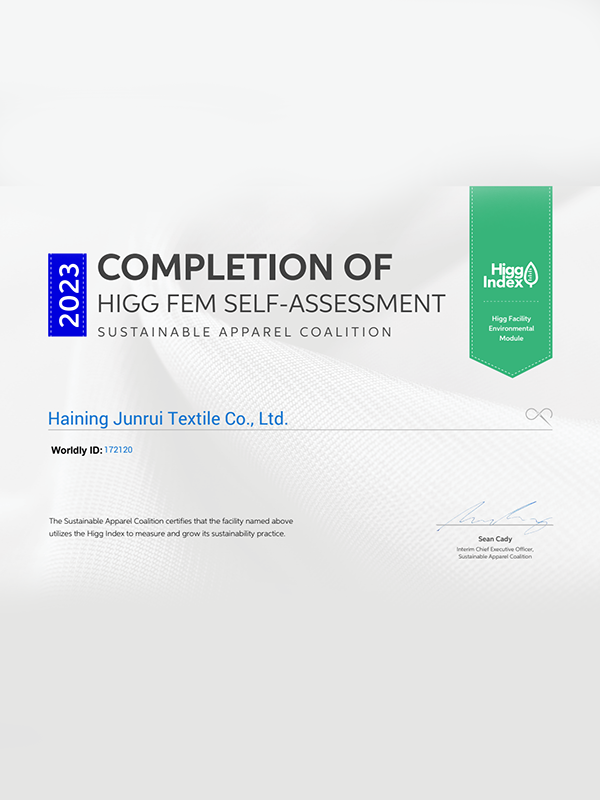

Haining Junrui Textile Co., Ltd. is a branch of Taiwan Artron Industrial Co., LTD. Since 1991→ Artron Dyeing & Weaving Co., Ltd. was established in 2000 → Yayun Trading Co., Ltd. was established in 2014 → Haining Jungrui Textile Co., Ltd. was established in 2022. Haining Jungrui Textile Co., Ltd. has more than 30 years of production and sales experience in the textile field.

As a China Custom All Polyester Jacquard Fabric For Fashion Clothing Manufacturers and All Polyester Jacquard Fabric For Fashion Clothing Suppliers, we are committed to the production of high-quality fabrics, to provide customers with high-quality service, products are exported to the United States, Europe, Japan, Australia, Southeast Asia, and other countries and regions.

News

-

Industry News 2026-02-05

Warp knitting fabrics have become an essential component in various industries, ranging from fashion to industrial applications. With their unique structure and qualities, they offer distinct advantages over other types ...

View More -

Industry News 2026-01-29

Introduction to Tricot Fabric Tricot fabric, known for its unique structure and versatile applications, has become a popular choice in the garment industry. Made from a knit structure, this fabric is widely used for prod...

View More -

Industry News 2026-01-22

Introduction Sportswear has evolved from basic functionality to a vital component of modern athletic performance. The fabric used in sportswear plays an essential role in determining comfort, durability, and overall perf...

View More

All Polyester Jacquard Fabric KNOWLEDGE

In the process of producing All Polyester Jacquard Fabric for fashion clothing, what energy-saving and emission-reducing production processes did Haining Junrui Textile Co., Ltd. adopt to practice sustainable development?

1. Selection of environmentally friendly raw materials and dyes

When producing All Polyester Jacquard Fabric, Haining Junrui Textile Co., Ltd.'s primary concern is the selection of raw materials and dyes. The company uses environmentally friendly polyester fiber as raw material, which is recyclable and produces relatively less waste during the production process. The company also chooses to use bio-matrix dyes or low-toxic and high-efficiency dyes for dyeing, which are not only environmentally friendly, but also can reduce wastewater discharge and the generation of harmful substances.

2. Energy-saving and emission-reducing dyeing and finishing processes

Energy-saving dyeing and finishing technology:

The company can complete the dyeing process in a short time and reduce energy consumption by improving the dyeing and finishing process, such as using high temperature and high pressure dyeing technology.

The company also uses a short-process finishing process to simplify the production process and reduce wastewater discharge and energy consumption.

Optimize dyeing formula:

Haining Junrui Textile Co., Ltd. reasonably selects and adjusts the types of dyes, types of auxiliaries and dosages according to specific dyeing process requirements to reduce unnecessary ingredients and additives in the dye bath, thereby reducing the pollution load of wastewater.

The company also optimizes the dye formula to improve the utilization rate of dyes, reduce the consumption of dyes in the dyeing process, and further reduce wastewater discharge.

Intelligent control:

During the dyeing process, the company uses an automatic control system to control dyeing process parameters such as temperature, time, pH value, etc. to improve the stability of the dyeing process and reduce the generation of wastewater.

Use intelligent optimization algorithms, such as genetic algorithms and particle swarm optimization algorithms, to optimize dyeing process parameters, further reduce the consumption of dyes and auxiliaries, and reduce the pollution load of wastewater.

III. Efficient use and recycling of water resources

Circulating water system:

The company uses a circulating water system to treat printing and dyeing wastewater for recycling. Through advanced wastewater treatment technologies, such as membrane separation technology and biological treatment technology, the wastewater treatment efficiency is improved to ensure that the wastewater meets the discharge standards before recycling.

Water-saving equipment:

During the production process, the company uses water-saving equipment, such as spray dyeing machines, overflow dyeing machines, etc. These equipment can reduce water consumption while ensuring dyeing quality.

New dyeing process:

The company also uses new dyeing processes, such as dry dyeing and semi-dry dyeing, which can significantly reduce water consumption and reduce wastewater discharge.

IV. Waste gas treatment and resource utilization

Waste gas purification technology:

During the production process, the company uses adsorption, oxidation, condensation and other technologies to treat waste gas, effectively reducing the emission of harmful gases.

Waste gas resource utilization:

The company also actively explores ways to utilize waste gas resources, such as recycling useful substances in printing and dyeing waste gas and converting them into energy or other valuable products.

V. Solid waste treatment and resource utilization

Solid waste treatment technology:

For solid waste generated during the production process, such as printing waste residue, dyeing waste residue, etc., the company uses physical, chemical, biological and other methods to recycle or safely dispose of them to reduce environmental pollution.

Resource Utilization:

The company is also actively exploring ways to utilize solid waste resources, such as burning printing waste residues and using them as fuel, or landfilling waste residues in landfills that meet environmental protection requirements and developing them as resources.

VI. Energy Management System and Continuous Improvement

Energy Management System:

Haining Junrui Textile Co., Ltd. uses an energy management system to monitor and manage the energy consumption of printing and dyeing enterprises, timely discovers energy waste problems through data analysis, and takes effective measures to improve them.

Continuous Improvement:

The company also focuses on continuously improving production processes and procedures, and constantly explores new energy-saving and emission-reduction technologies and methods to further improve production efficiency, reduce energy consumption and reduce environmental pollution.

English

English 中文简体

中文简体 Español

Español 日本語

日本語