Submit feedback

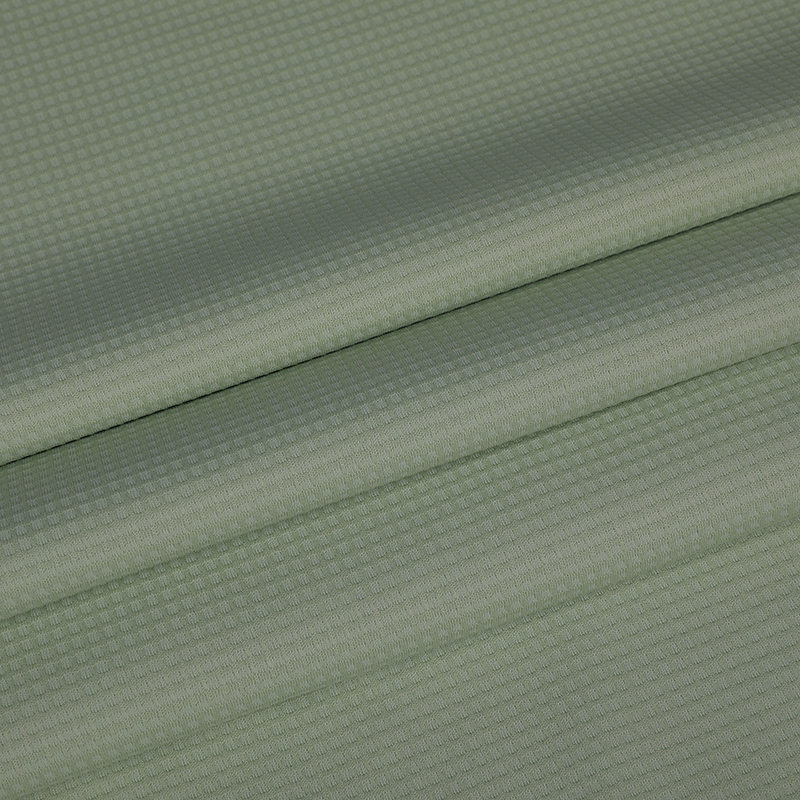

Custom Polyester Knitted Elastic Fabric For Sportswear

About Us

Haining Junrui Textile Co., Ltd. is a branch of Taiwan Artron Industrial Co., LTD. Since 1991→ Artron Dyeing & Weaving Co., Ltd. was established in 2000 → Yayun Trading Co., Ltd. was established in 2014 → Haining Jungrui Textile Co., Ltd. was established in 2022. Haining Jungrui Textile Co., Ltd. has more than 30 years of production and sales experience in the textile field.

As a China Custom Polyester Knitted Elastic Fabric For Sportswear Manufacturers and Polyester Knitted Elastic Fabric For Sportswear Suppliers, we are committed to the production of high-quality fabrics, to provide customers with high-quality service, products are exported to the United States, Europe, Japan, Australia, Southeast Asia, and other countries and regions.

News

-

Industry News 2026-02-13

Introduction The world of athletic apparel has seen remarkable advancements in fabric technology, with an increasing demand for materials that are both functional and comfortable. One of the key innovations in recent yea...

View More -

Industry News 2026-02-05

Warp knitting fabrics have become an essential component in various industries, ranging from fashion to industrial applications. With their unique structure and qualities, they offer distinct advantages over other types ...

View More -

Industry News 2026-01-29

Introduction to Tricot Fabric Tricot fabric, known for its unique structure and versatile applications, has become a popular choice in the garment industry. Made from a knit structure, this fabric is widely used for prod...

View More

Polyester Knitted Elastic Fabric KNOWLEDGE

How to control the quality of polyester knitted elastic fabric for sportswear? Do you conduct finished product inspection and performance testing?

In the initial stage of polyester knitted elastic fabric for sportswear - raw material selection, JUNRUI has demonstrated its deep understanding and practice of environmental protection concepts. The company uses strictly screened environmentally friendly raw materials and dyes, which not only meet international environmental standards, but also minimize the negative impact on the environment during the production process. For example, low-energy consumption and low-emission polyester fibers are selected as the base material. This material not only has good elasticity and wear resistance, but is also easy to recycle and reuse, which meets the requirements of sustainable development. At the same time, the dyes used are all environmentally friendly dyes to ensure that no harmful substances are released during the dyeing process, protecting water resources and the ecological environment.

The improvement of production technology is a key link in improving fabric quality. JUNRUI uses advanced energy-saving and emission-reduction production technologies, such as closed-loop water circulation systems and heat recovery systems, which effectively reduce energy and water consumption in the production process and reduce the generation of waste. In the knitting process, the company introduced high-precision computerized flat knitting machines to ensure the stability and uniformity of the fabric structure by precisely controlling the tension, feeding speed and weaving density of the yarn, thereby improving the elasticity and comfort of the fabric. The addition of elastic fibers has also been carefully calculated and tested to ensure that the fabric will not be deformed due to excessive stretching while maintaining good elasticity, thus extending the service life of the sportswear.

In order to ensure the high quality of polyester knitted elastic fabric for sportswear, JUNRUI has established a complete quality control system. This system covers every link from raw material storage, production and processing to finished product delivery. It has passed the ISO 9001 quality management system certification to ensure that every step of the operation has rules to follow and can be traced. In the fabric production stage, the company uses an intelligent monitoring system to monitor the temperature, humidity and fabric tension of the production line in real time. Once an abnormality is found, the system will immediately alarm and automatically adjust, effectively avoiding quality problems caused by human operation errors.

Finished product inspection and performance testing are an indispensable part of the quality control process. At JUNRUI, every piece of polyester knitted stretch sportswear fabric will undergo strict finished product inspection after production. This includes but is not limited to appearance inspection (such as color difference, defects), dimensional stability test (to ensure that the fabric is not easily deformed after washing), elastic recovery test (to evaluate the recovery ability of the fabric after repeated stretching), breathability test (to ensure that sweat can evaporate quickly during exercise and stay dry) and wear resistance test (to simulate the wear and tear in daily use and evaluate the durability of the fabric). These tests not only follow national or industry standards, but also often exceed the standards, hold themselves to higher standards, and ensure the excellent performance of the final product.

It is particularly worth mentioning that for stretch fabrics, the company has also introduced special elastic recovery test equipment, which simulates the stretching and recovery process during human exercise, accurately measures the elastic retention rate of the fabric, and ensures that the fabric can still maintain good fit and comfort after long-term wear.

While meeting basic quality control, JUNRUI also deeply understands the personalized needs of different customers for polyester knitted stretch sportswear fabrics. Whether it is a complex custom order or a large-scale production demand, the company can provide tailor-made solutions with its strong R&D team and flexible production capacity. By communicating closely with customers and understanding their specific application scenarios, the wearer's body characteristics and exercise habits, the company can design fabrics that are both in line with fashion trends and meet functional needs, ensuring that the final product has unique competitiveness in the market.

Stable supply chain and production delivery capabilities are also important commitments made by the company to customers. From raw material procurement to finished product delivery, every link has been carefully planned and optimized to ensure that high-quality products are delivered on time and in quantity. The company has also established a complete after-sales service system to continuously track the products sold, collect customer feedback in a timely manner, and continuously optimize products and services to achieve a win-win situation with customers.

English

English 中文简体

中文简体 Español

Español 日本語

日本語