Submit feedback

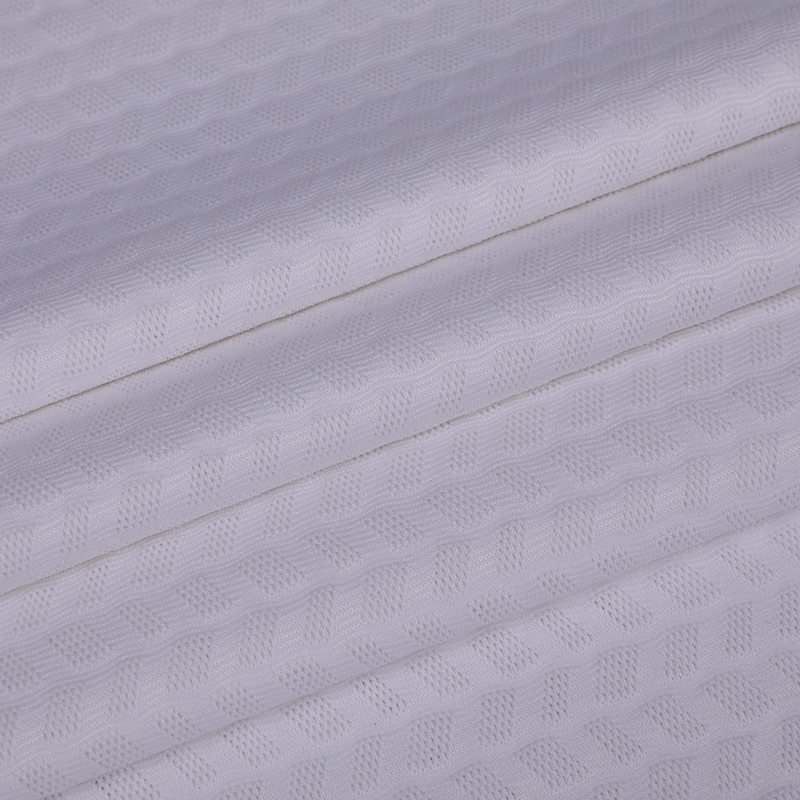

Custom Polyester Ammonia Jacquard Elastic Fabric For Sportswear

About Us

Haining Junrui Textile Co., Ltd. is a branch of Taiwan Artron Industrial Co., LTD. Since 1991→ Artron Dyeing & Weaving Co., Ltd. was established in 2000 → Yayun Trading Co., Ltd. was established in 2014 → Haining Jungrui Textile Co., Ltd. was established in 2022. Haining Jungrui Textile Co., Ltd. has more than 30 years of production and sales experience in the textile field.

As a China Custom Polyester Ammonia Jacquard Elastic Fabric For Sportswear Manufacturers and Polyester Ammonia Jacquard Elastic Fabric For Sportswear Suppliers, we are committed to the production of high-quality fabrics, to provide customers with high-quality service, products are exported to the United States, Europe, Japan, Australia, Southeast Asia, and other countries and regions.

News

-

Industry News 2026-02-13

Introduction The world of athletic apparel has seen remarkable advancements in fabric technology, with an increasing demand for materials that are both functional and comfortable. One of the key innovations in recent yea...

View More -

Industry News 2026-02-05

Warp knitting fabrics have become an essential component in various industries, ranging from fashion to industrial applications. With their unique structure and qualities, they offer distinct advantages over other types ...

View More -

Industry News 2026-01-29

Introduction to Tricot Fabric Tricot fabric, known for its unique structure and versatile applications, has become a popular choice in the garment industry. Made from a knit structure, this fabric is widely used for prod...

View More

Polyester Ammonia Jacquard Elastic Fabric KNOWLEDGE

What are the special requirements for shrinkage treatment and ironing of polyester ammonia jacquard elastic fabric for sportswear? How to ensure the stability of fabric size?

Polyester (polyester fiber) is known for its high strength, wear resistance and good wrinkle resistance, while spandex is known for its excellent elasticity. The combination of the two makes polyester ammonia blended fabrics an ideal choice for making sportswear, especially fabrics with jacquard designs, which are not only beautiful but also provide good breathability and comfort. However, this type of fabric has special challenges in shrinkage treatment and ironing, mainly due to its elastic properties and complex structure.

Special requirements for shrinkage treatment

Pre-shrinkage treatment: Polyester ammonia jacquard fabrics are prone to a certain degree of dimensional change during the first wash, so pre-shrinkage treatment is required at the beginning of production. JUNRUI uses advanced pre-shrinkage technology to simulate multiple washing processes by precisely controlling water temperature, time and mechanical tension, effectively reducing the subsequent shrinkage rate of the fabric and ensuring the stability of the finished product size. In this process, the company pays special attention to environmental protection and uses harmless chemical additives to reduce the impact on the environment.

Temperature and humidity control: Precise control of temperature and humidity is essential during shrinkage treatment. JUNRUI is equipped with a high-precision temperature and humidity control system to ensure a stable treatment environment and avoid uneven shrinkage of fabrics due to temperature and humidity fluctuations.

Tension management: Tension management is particularly critical for stretch fabrics containing spandex. During the shrinkage treatment process, JUNRUI uses an intelligent tension control system to ensure that the fabric is pre-shrunk under uniform and moderate tension, avoiding local excessive stretching or shrinkage, and maintaining the overall flatness and elasticity of the fabric.

Special requirements for ironing and shaping

Temperature setting: Polyester and spandex have different thermal sensitivities, and the temperature must be accurately set during ironing. Too high a temperature may damage the spandex fiber and reduce its elasticity; too low a temperature cannot be effectively shaped. JUNRUI uses advanced ironing equipment and combines the characteristics of the fabric to set the most suitable ironing temperature, which not only ensures the shaping effect of the fabric, but also avoids damage to the fabric performance.

Pressure and time control: The pressure and time during ironing also affect the final effect of the fabric. JUNRUI uses a pressure-adjustable ironing machine to flexibly adjust the ironing pressure according to the thickness and elasticity requirements of the fabric. At the same time, through the precise timing system, it ensures that each piece of fabric can get the right ironing time to achieve the best shaping effect.

Steam use: The right amount of steam can help the fabric to better shape, while reducing direct thermal damage to the fabric. During the ironing process, JUNRUI uses an efficient and energy-saving steam generation system to provide stable and appropriate steam, which not only improves ironing efficiency but also protects the quality of the fabric.

Comprehensive strategy to ensure the dimensional stability of fabrics

Raw material selection: Starting from the source, JUNRUI strictly screens suppliers to ensure that the polyester and spandex raw materials are of high quality and have stable physical properties, which is the basis for ensuring the dimensional stability of the fabric.

Production process optimization: During the production process, the company continuously optimizes the production process, such as using low-tension weaving technology to reduce the deformation of the fabric during the production process; in the dyeing and finishing stages, environmentally friendly and stable dyes and auxiliaries are used to reduce the dimensional changes of the fabric caused by chemical treatment.

Quality control system: Establish a complete quality control system, from raw materials entering the warehouse to finished products leaving the factory, each process is strictly inspected. Especially for shrinkage and dimensional stability tests, internationally advanced testing equipment and methods are used to ensure that each batch of fabrics can meet the standards required by customers.

Customer customized services: In response to customers' special needs, such as specific shrinkage control or ironing shaping requirements, JUNRUI provides customized services. Through close communication with customers and combining the company's technical strength, we develop fabric solutions that meet specific needs.

English

English 中文简体

中文简体 Español

Español 日本語

日本語