Submit feedback

Custom Nylon Ammonia Jacquard Elastic Fabric For Sportswear

About Us

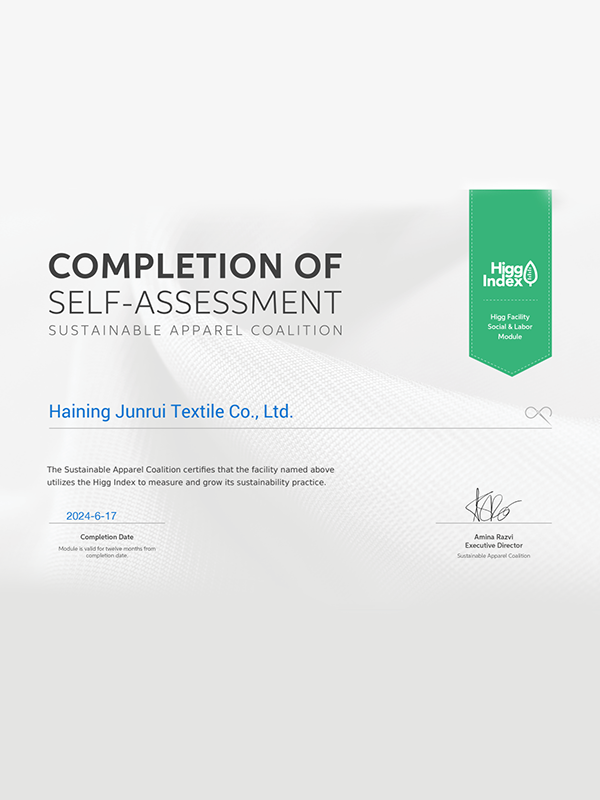

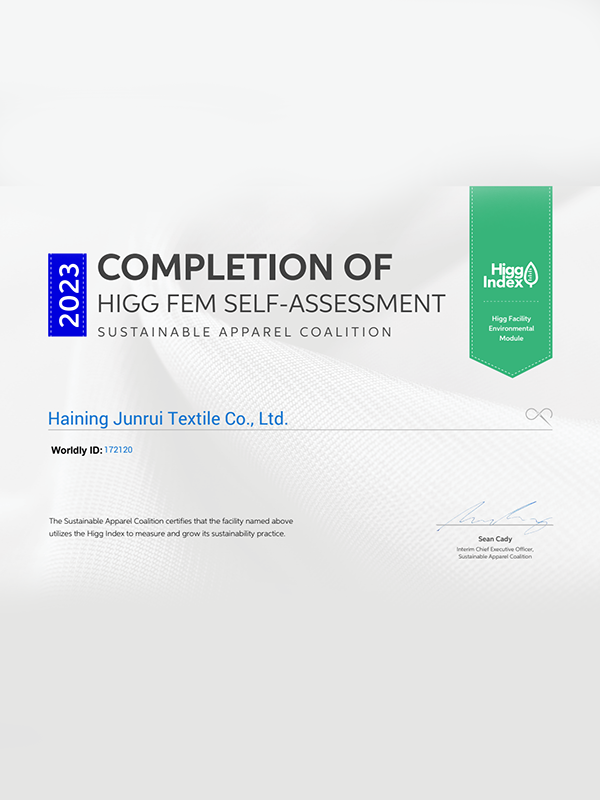

Haining Junrui Textile Co., Ltd. is a branch of Taiwan Artron Industrial Co., LTD. Since 1991→ Artron Dyeing & Weaving Co., Ltd. was established in 2000 → Yayun Trading Co., Ltd. was established in 2014 → Haining Jungrui Textile Co., Ltd. was established in 2022. Haining Jungrui Textile Co., Ltd. has more than 30 years of production and sales experience in the textile field.

As a China Custom Nylon Ammonia Jacquard Elastic Fabric For Sportswear Manufacturers and Nylon Ammonia Jacquard Elastic Fabric For Sportswear Suppliers, we are committed to the production of high-quality fabrics, to provide customers with high-quality service, products are exported to the United States, Europe, Japan, Australia, Southeast Asia, and other countries and regions.

News

-

Industry News 2026-02-13

Introduction The world of athletic apparel has seen remarkable advancements in fabric technology, with an increasing demand for materials that are both functional and comfortable. One of the key innovations in recent yea...

View More -

Industry News 2026-02-05

Warp knitting fabrics have become an essential component in various industries, ranging from fashion to industrial applications. With their unique structure and qualities, they offer distinct advantages over other types ...

View More -

Industry News 2026-01-29

Introduction to Tricot Fabric Tricot fabric, known for its unique structure and versatile applications, has become a popular choice in the garment industry. Made from a knit structure, this fabric is widely used for prod...

View More

Nylon Ammonia Jacquard Elastic Fabric KNOWLEDGE

During the shaping process of nylon ammonia jacquard elastic fabric for sportswear, how does your company control the temperature and time to ensure the dimensional stability and elasticity stability of the fabric? Are multiple shaping processes performed?

Shaping is a crucial part of the production process of nylon ammonia jacquard elastic fabric for sportswear, which directly affects the dimensional retention and elastic recovery of the finished product. At JUNRUI, we use advanced temperature control systems and precise timing devices to strictly control the temperature and time during the shaping process.

In view of the characteristics of nylon spandex blended fabrics, we set a specific shaping temperature range. This range is determined based on a large amount of experimental data, aiming to find the best temperature point that can effectively fix the fabric structure without compromising its elasticity and wear resistance. The temperature distribution in the shaping machine is monitored in real time by an infrared thermometer to ensure that every inch of the fabric is evenly heated to avoid fabric damage or performance degradation caused by local overheating. Our shaping equipment is equipped with an intelligent temperature control system that can automatically adjust the temperature according to the fabric type, thickness and required performance to achieve precise control.

The determination of the shaping time is also crucial. Too long or too short a shaping time may affect the final performance of the fabric. At JUNRUI, we have established a detailed shaping schedule for fabrics of different specifications through repeated experiments. This schedule records in detail the time required for each stage from the fabric entering the shaping machine to the completion of shaping, ensuring that every step is just right. We also use advanced sensor technology to monitor the state changes of the fabric during the shaping process in real time. Once the preset conditions are met, the shaping process is automatically adjusted or terminated immediately to ensure the best performance of the fabric.

In order to further improve the dimensional stability and elastic stability of nylon spandex jacquard stretch fabrics, JUNRUI will selectively perform multiple shaping treatments based on the specific requirements of the fabric and customer customization needs. This strategy is based on our in-depth understanding of fabric characteristics and accurate grasp of market demand.

After the first shaping, we will strictly test the dimensional change rate and elastic recovery rate of the fabric. For fabrics that require higher stability requirements, we will implement secondary or even tertiary shaping, and detailed analysis and adjustments will be carried out between each shaping to ensure that each treatment can have a positive impact on the performance of the fabric, while avoiding performance degradation caused by excessive treatment. Through multiple shaping, we can not only significantly improve the dimensional stability of the fabric, but also effectively enhance the wrinkle resistance and durability of the fabric, making it more suitable for making high-end sportswear.

In the process of achieving precise temperature and time control and multiple shaping treatments, JUNRUI's technological innovation and optimized production process played a key role. We have introduced internationally leading textile production equipment, which is not only highly automated, but also highly flexible and programmable, and can meet the shaping needs of different fabric types. We continue to optimize the production process, and through the introduction of intelligent management systems, we can achieve real-time monitoring and analysis of production data to ensure that every step of the operation can reach the optimal state.

JUNRUI is well aware that in today's growing demand for customization, providing personalized customization services is an important magic weapon to win the market. Therefore, we not only provide standard shaping treatment solutions, but also tailor-made shaping solutions according to customer specific needs, such as fabric composition, elasticity level, color fastness, etc. Our technical team will work closely with customers, from fabric selection to shaping process design, and strive to accurately match customer needs at every step to ensure that the final product can meet its special market positioning and customer groups.

English

English 中文简体

中文简体 Español

Español 日本語

日本語