Submit feedback

Custom High Stretch Brocade Fabric For Fashion Clothing

About Us

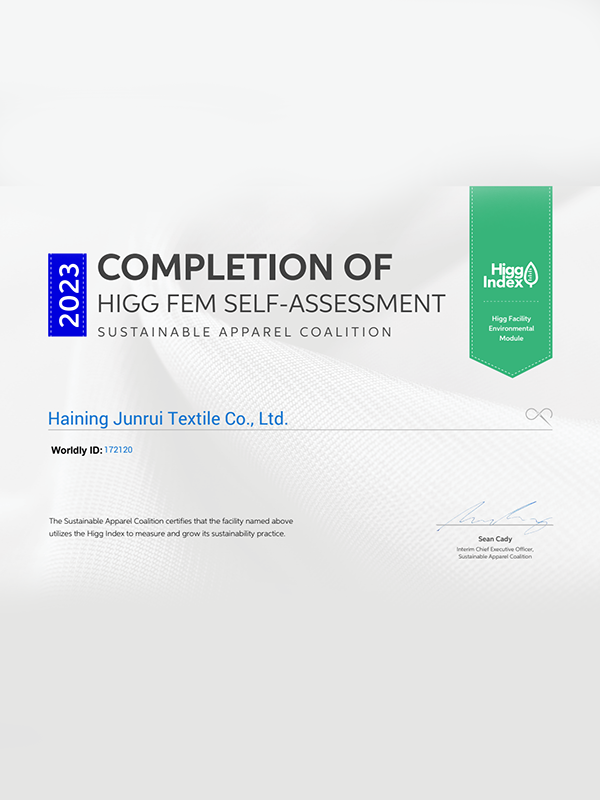

Haining Junrui Textile Co., Ltd. is a branch of Taiwan Artron Industrial Co., LTD. Since 1991→ Artron Dyeing & Weaving Co., Ltd. was established in 2000 → Yayun Trading Co., Ltd. was established in 2014 → Haining Jungrui Textile Co., Ltd. was established in 2022. Haining Jungrui Textile Co., Ltd. has more than 30 years of production and sales experience in the textile field.

As a China Custom High Stretch Brocade Fabric For Fashion Clothing Manufacturers and High Stretch Brocade Fabric For Fashion Clothing Suppliers, we are committed to the production of high-quality fabrics, to provide customers with high-quality service, products are exported to the United States, Europe, Japan, Australia, Southeast Asia, and other countries and regions.

News

-

Industry News 2026-02-13

Introduction The world of athletic apparel has seen remarkable advancements in fabric technology, with an increasing demand for materials that are both functional and comfortable. One of the key innovations in recent yea...

View More -

Industry News 2026-02-05

Warp knitting fabrics have become an essential component in various industries, ranging from fashion to industrial applications. With their unique structure and qualities, they offer distinct advantages over other types ...

View More -

Industry News 2026-01-29

Introduction to Tricot Fabric Tricot fabric, known for its unique structure and versatile applications, has become a popular choice in the garment industry. Made from a knit structure, this fabric is widely used for prod...

View More

High Stretch Brocade Fabric KNOWLEDGE

What energy-saving and emission-reducing production processes does Haining Junrui Textile Co., Ltd.'s High Stretch Brocade Fabric for fashion clothing use to support sustainable development?

1. Selection of environmentally friendly raw materials and dyes

Haining Junrui Textile starts from the source and selects environmentally friendly raw materials and dyes as the basis for production. These raw materials and dyes are low in toxicity, biodegradable or easily recyclable, thereby reducing pollution to the environment during production and use. The company may use natural fibers such as organic cotton and bamboo fiber as raw materials, which do not require a large amount of fertilizers and pesticides during growth and are more environmentally friendly. In terms of dye selection, the company tends to use bio-matrix dyes or environmentally friendly synthetic dyes, which produce wastewater that is easier to handle during the dyeing process and have less impact on the environment.

2. Energy-saving dyeing and finishing technology

During the dyeing and finishing process, Haining Junrui Textile uses energy-saving dyeing and finishing technologies to reduce energy consumption and wastewater discharge. These technologies include but are not limited to:

High temperature and high pressure dyeing: By increasing the dyeing temperature and pressure, the diffusion rate of the dye in the fiber can be accelerated, thereby shortening the dyeing time and reducing energy consumption. High temperature and high pressure conditions also help improve the uniformity and fastness of dyeing.

Short process finishing: The traditional dyeing and finishing process often includes multiple steps, each of which consumes energy and water resources. The short process finishing technology achieves a more efficient and energy-saving production process by optimizing process parameters and integrating steps.

Cold transfer printing: This is a new printing technology that can achieve dye transfer and fixation at a lower temperature. Compared with traditional heat transfer printing, cold transfer printing can significantly reduce energy consumption and wastewater discharge.

3. Water resource recycling

Water resources are one of the indispensable resources in the textile production process. In order to reduce the use of fresh water resources and reduce wastewater discharge, Haining Junrui Textile has implemented a water resource recycling system. The system uses advanced wastewater treatment technology to purify the wastewater in the production process to meet the standards for reuse. Then, the treated water can be reused in the cleaning, cooling and other links in the production process, thereby achieving efficient use of water resources.

4. Waste gas purification technology

In the textile production process, waste gas emissions are also an issue that cannot be ignored. In order to reduce the emission of harmful gases, Haining Junrui Textile has adopted waste gas purification technology. These technologies include steps such as adsorption, oxidation, and condensation, which can effectively remove harmful substances in exhaust gas, such as particulate matter, volatile organic compounds, etc. By implementing exhaust gas purification technology, the company not only reduces pollution to the atmosphere, but also improves the air quality of the production environment.

V. Energy Management System

In order to more effectively manage energy consumption and reduce production costs, Haining Junrui Textile has established a complete energy management system. The system helps the company to achieve refined management of energy consumption by real-time monitoring of energy consumption, analyzing energy efficiency, and proposing improvement suggestions. The system is also combined with the company's production management system to achieve energy optimization scheduling and intelligent control in the production process.

VI. Intelligent production and automated control

In the production process of High Stretch Brocade Fabric for fashion clothing, Haining Junrui Textile has also actively introduced intelligent production and automated control technologies. These technologies improve production efficiency and product quality by precisely controlling each link in the production process, and reduce the impact of human factors on the production process. The company may have adopted advanced technologies such as automated textile equipment and intelligent detection systems to achieve automation and intelligent control of the production process.

7. Continuous technological innovation and R&D investment

In order to continuously promote the green transformation of the production process and the innovative application of energy-saving and emission-reduction technologies, Haining Junrui Textile has invested a lot of R&D funds and technical forces. The company has a professional R&D team dedicated to developing more environmentally friendly and efficient textile production technologies and products. The company has also established close cooperative relations with well-known scientific research institutions and universities at home and abroad to jointly promote the sustainable development of the textile industry.

English

English 中文简体

中文简体 Español

Español 日本語

日本語