Submit feedback

What Are the Key Features of Warp Knitting Fabric?

2025-12-05

Warp knitting fabric is a versatile textile widely used across multiple industries, ranging from sportswear to home textiles. As one of the fundamental types of knitted fabrics, warp knitting distinguishes itself from weft knitting through its unique production method, structural characteristics, and material adaptability.

Introduction to Warp Knitting Fabric

Warp knitting is a method of constructing fabric where each yarn loop is formed vertically along the warp direction, as opposed to weft knitting, where loops are formed horizontally. This distinction significantly impacts the fabric’s strength, stability, and elasticity, making warp knitting fabric ideal for applications requiring durability and structural integrity.

Key advantages of warp knitting include:

- High dimensional stability

- Resistance to runs or laddering

- Ability to produce complex patterns

- Efficient large-scale production

The wide range of fibers used in warp knitting fabric includes polyester, nylon, spandex, and blends thereof, each offering specific performance characteristics. In particular, polyester swimwear fabric has gained prominence in sports and leisure apparel due to its durability, quick-drying properties, and resistance to chlorine and UV exposure.

Structural Features of Warp Knitting Fabric

Warp knitting fabric is characterized by its unique loop formation and interlacing method. Unlike weft knitting, which is more prone to stretching along the width of the fabric, warp-knitted fabrics are inherently stable and resistant to deformation.

The structural advantages include:

- Dimensional stability: The vertical loop alignment minimizes fabric distortion under stress.

- High tear resistance: The interconnected loops distribute stress across the fabric, preventing easy tearing.

- Customizable porosity: Fabrics can be engineered to allow ventilation, moisture-wicking, or water resistance.

Comparative Features of Warp Knitting Fabric vs. Weft Knitting Fabric

| Feature | Warp Knitting Fabric | Weft Knitting Fabric |

|---|---|---|

| Loop Formation | Vertical (along warp yarns) | Horizontal (along weft yarns) |

| Dimensional Stability | High | Moderate |

| Run/Ladder Resistance | Excellent | Poor |

| Stretchability | Low (width direction) | High (width direction) |

| Pattern Complexity | Moderate to High | Limited |

| Typical Applications | Sportswear, upholstery, industrial textiles | T-shirts, casual knitwear |

The table highlights how warp knitting fabric is especially suitable for applications that require structural stability and durability, whereas weft-knitted fabrics are favored for high-stretch and comfort-focused garments.

Types of Warp Knitting Fabric

Warp knitting fabric can be divided into several types based on the knitting machine used, yarn configuration, and end-use. Common types include:

-

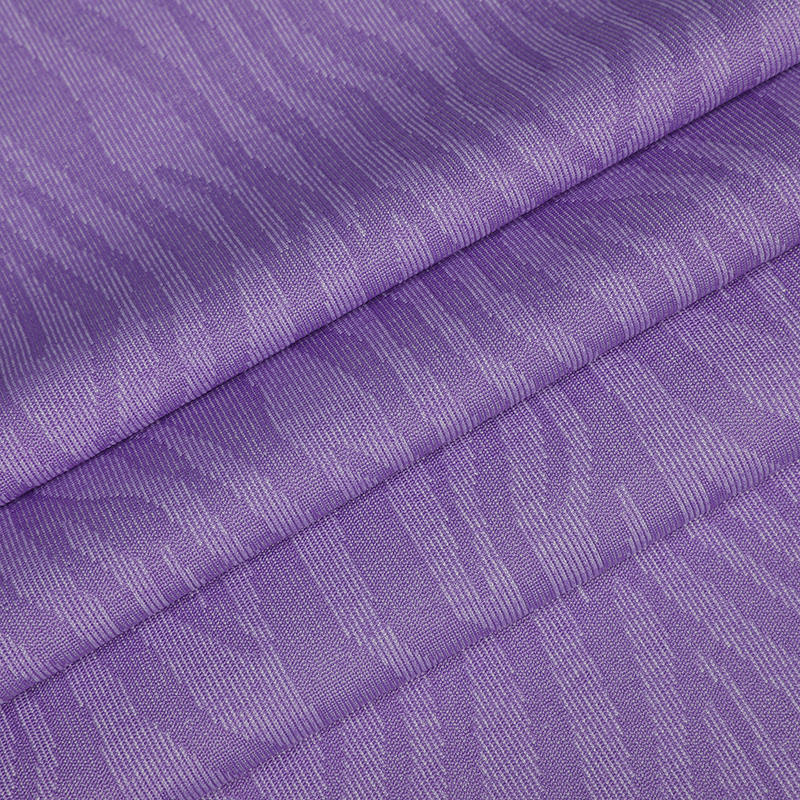

Tricot Fabric:

- Smooth surface, fine texture

- Widely used in lingerie, polyester swimwear fabric, and sportswear

-

Raschel Fabric:

- Open mesh structure, lace-like patterns possible

- Used in home textiles, netting, and medical fabrics

-

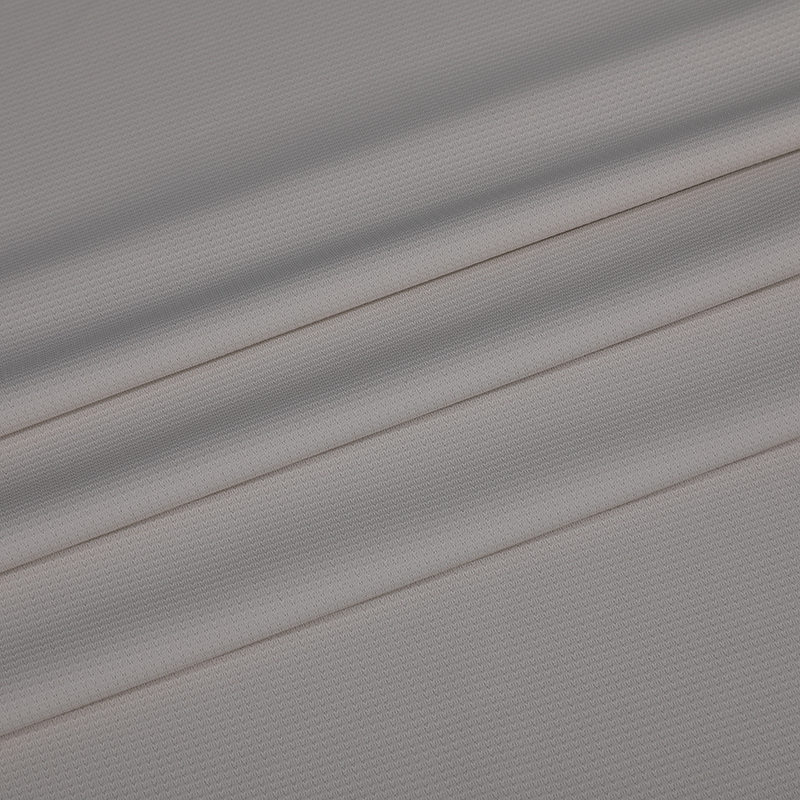

Milano and Double Knitting Variants:

- Thicker, more structured fabrics

- Applied in outerwear, functional textiles, and upholstery

Each type of warp knitting fabric can be engineered for specific properties, such as moisture-wicking, breathability, or elasticity. For instance, polyester swimwear fabric produced via tricot knitting provides lightweight, quick-drying, and chlorine-resistant features, essential for aquatic sportswear.

Material Selection and Fiber Integration

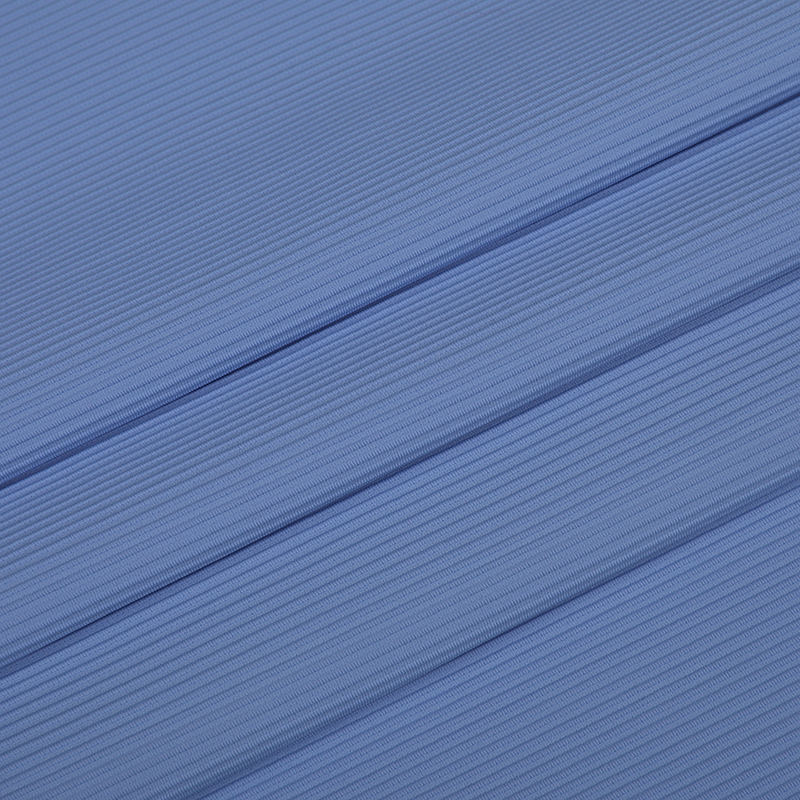

The choice of fiber significantly influences the performance and application of warp knitting fabric. Common fibers include:

- Polyester: High durability, resistance to sunlight, dimensional stability

- Nylon: Strong, lightweight, smooth hand feel

- Spandex/Elastane: Provides stretch and recovery, often blended for sportswear

- Blended Fabrics: Combining fibers allows the designer to tailor mechanical, thermal, and aesthetic properties

Table 2 illustrates common fiber types used in warp knitting fabrics and their key properties:

Fiber Types and Performance in Warp Knitting Fabric

| Fiber Type | Key Properties | Typical Applications |

|---|---|---|

| Polyester | Durable, UV-resistant, quick-drying | Swimwear, sportswear, industrial textiles |

| Nylon | High strength, smooth texture | Lingerie, athletic wear, nets |

| Spandex/Elastane | Elastic, recovery | Compression garments, activewear |

| Cotton | Soft, breathable | Apparel, home textiles |

| Blended Fibers | Balanced performance and comfort | Functional sportswear, outerwear |

Material selection, combined with warp knitting techniques, allows manufacturers to create fabrics that meet specific functional requirements, from high-performance swimwear to structurally robust industrial textiles.

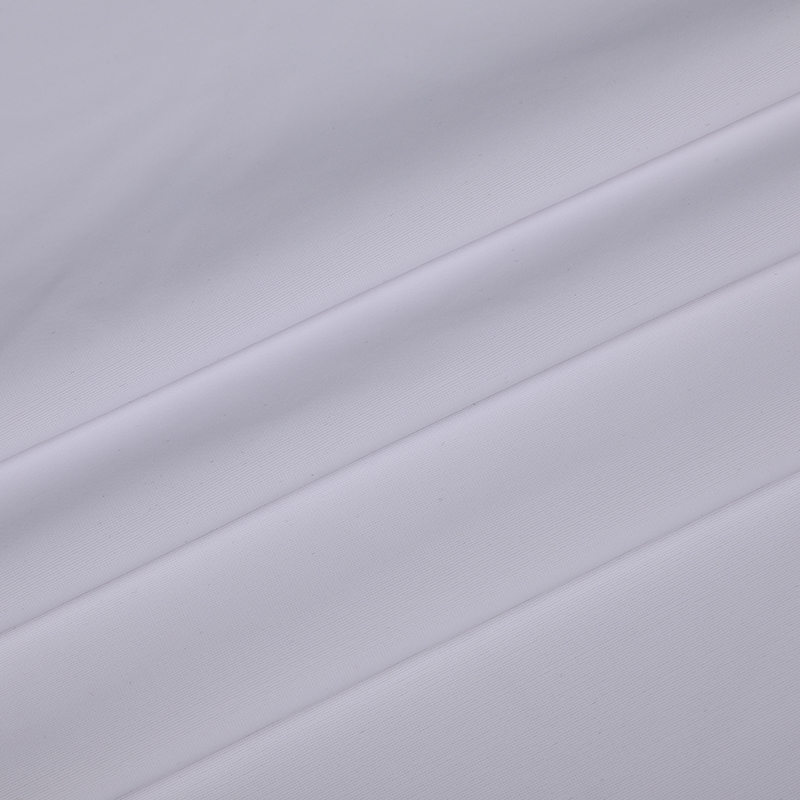

Performance Characteristics of Warp Knitting Fabric

Warp knitting fabric is valued not only for its structural advantages but also for its functional versatility. Performance characteristics often targeted in industrial and consumer applications include:

- Stretch and Recovery: Limited stretch along the width ensures garments maintain shape. Stretch can be enhanced using spandex blends.

- Moisture Management: Warp knitting fabric can be engineered to wick moisture away from the skin, making it ideal for activewear and swimwear.

- Durability: Resistance to abrasion, runs, and pilling prolongs fabric life, particularly in high-performance garments.

- Thermal Properties: Fabrics can be adapted for heat retention or breathability, depending on fiber choice and structure.

- Aesthetic Versatility: Warp knitting allows intricate patterns, lace-like structures, and smooth surfaces suitable for fashion-oriented applications.

The combination of these characteristics makes warp knitting fabric highly adaptable for multiple industries, from apparel to medical and industrial sectors.

Common Applications of Warp Knitting Fabric

Warp knitting fabric has widespread use due to its versatility, stability, and performance. Key application areas include:

-

Sportswear and Swimwear:

- Polyester swimwear fabric is a staple, offering chlorine resistance, lightweight properties, and quick drying.

- Activewear garments benefit from structured support, breathability, and moisture management.

-

Home Textiles:

- Raschel warp knits are used for curtains, nets, and decorative fabrics due to their open mesh and patterning capabilities.

-

Industrial Textiles:

- Fabrics are used for filtration, automotive interiors, geotextiles, and reinforcement due to strength and dimensional stability.

-

Medical Applications:

- Warp-knitted meshes and bandages provide structural support and controlled elasticity.

The adaptability of warp knitting fabric demonstrates its unique position in textile manufacturing, bridging functional performance with aesthetic appeal.

Manufacturing Techniques of Warp Knitting Fabric

Warp knitting machines use multiple yarns fed in parallel along the warp direction. The key elements of the manufacturing process include:

- Yarn Feeding: Warp yarns are individually threaded through guides and needles.

- Loop Formation: Hooks or latch needles interlace the yarn to form loops in the vertical direction.

- Pattern Control: Mechanical or electronic jacquard systems can create complex textures, openwork designs, or three-dimensional structures.

- Finishing Processes: Fabrics may undergo heat-setting, dyeing, coating, or laminating to enhance functional properties such as stretch, water resistance, or colorfastness.

Advanced machinery allows for high-speed production, precise pattern control, and integration of multi-fiber systems, making warp knitting a highly efficient and flexible manufacturing method.

Advantages and Limitations

Advantages

- High dimensional stability and strength

- Ability to produce complex patterns and textures

- Versatility in fiber selection and performance properties

- Resistance to runs, tears, and abrasion

Limitations

- Lower elasticity compared to weft knitting

- Production requires specialized machinery and expertise

- Some warp-knitted fabrics may have less drape or softness

Understanding these advantages and limitations is crucial for textile designers and manufacturers seeking to maximize the functional and aesthetic potential of warp knitting fabric.

Conclusion

Warp knitting fabric represents a unique intersection of durability, versatility, and functional performance in the textile industry. With its structural stability, adaptability to different fibers, and suitability for high-performance applications, warp knitting fabric continues to be a preferred choice for sportswear, swimwear, industrial textiles, and more. Polyester swimwear fabric, in particular, demonstrates the specific advantages of warp knitting in producing high-quality, resilient, and functional garments.

FAQ

Q1: What is the main difference between warp knitting fabric and weft knitting fabric?

A: Warp knitting fabric has vertical loops along the yarn direction, providing high dimensional stability and resistance to runs, while weft knitting fabric has horizontal loops and offers higher elasticity.

Q2: Why is polyester swimwear fabric commonly made with warp knitting?

A: Warp knitting provides stability, quick-drying properties, chlorine resistance, and smooth surface, making it ideal for swimwear.

Q3: Can warp knitting fabric be used for industrial applications?

A: Yes, its strength, durability, and customizable structures make it suitable for filtration, automotive, geotextiles, and reinforcement purposes.

Q4: What fibers are typically used in warp knitting fabrics?

A: Common fibers include polyester, nylon, spandex/elastane, cotton, and blends to optimize performance characteristics.

English

English 中文简体

中文简体 Español

Español 日本語

日本語