Submit feedback

How to balance elasticity and quick-drying performance in matte warp knitted swimsuit fabric

2025-06-26

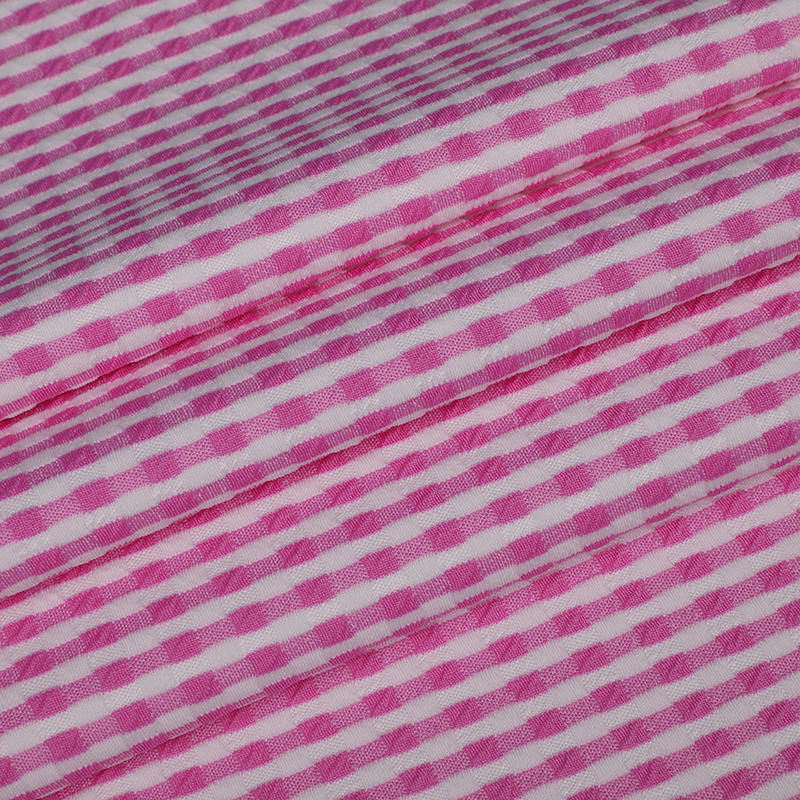

Structural characteristics and elastic optimization of Tricot fabric

Tricot fabric is a fabric made of warp knitting process, with structural features such that longitudinal (warp) yarns are tightly woven while transverse (weft) yarns are relatively loose. This structure gives the fabric good longitudinal elasticity and lateral stability, making it ideal for swimsuit making.

For higher elasticity, Tricot fabric usually uses spandex (Spandex) or Lycra® blended yarns. The addition of spandex gives the fabric excellent rebound performance and can maintain its original shape after multiple stretches. At the same time, the tight structure of the warp knitting process reduces yarn slippage, ensuring that the fabric is not easily deformed during movement.

In addition, the matte finish does not significantly affect the elasticity of the fabric. Through special matting fiber or post-tidying process, Tricot fabric can maintain elasticity while presenting a high-quality matte texture, meeting consumers' dual needs for beauty and function.

Key factors of quick-drying performance and optimization of Tricot fabric

Quick-drying performance is one of the core indicators of swimsuit fabrics. The quick-drying ability of Tricot fabric mainly depends on fiber selection, braid density and post-tissue process. Polyester fibers (Polyester) and Nylon) are common choices for swimsuit fabrics. They not only have good strength, but also enhance moisture diffusion through special-shaped cross-sectional fibers or hollow fiber structures.

In the weaving process, Tricot fabric's warp knit structure allows designers to adjust yarn density to optimize the fabric's breathability and moisture evaporation rate. Higher weaving density can improve the durability of the fabric, but may affect the quick-drying performance; while moderate loose structures can accelerate moisture discharge while maintaining sufficient support.

The post-tire process is also crucial to quick-drying performance. The application of moisture-absorbing additives can reduce moisture adsorption on the fiber surface and make sweat evaporate faster. In addition, some high-end Tricot fabrics will use hydrophilic coating or nanotreatment technology to further improve the quick-drying efficiency without affecting elasticity.

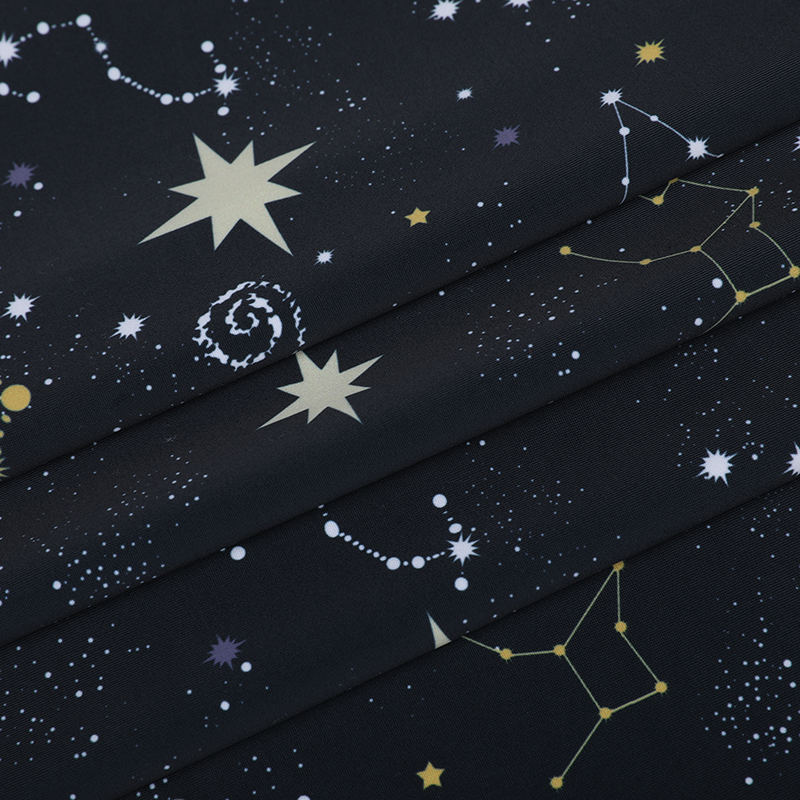

Synergistic optimization strategy for elasticity and quick-drying performance

In the development of swimsuit fabrics, elasticity and quick-drying performance are not mutually exclusive, but can be synergistically optimized through scientific proportions and process adjustments. The advantage of Tricot fabric is its flexibility in the weaving method, allowing manufacturers to adjust yarn combinations and structural parameters according to different needs.

For example, using high elastic spandex and quick-drying polyester blended yarns can improve the wet conduction ability of the fabric while ensuring tensile performance. At the same time, by adjusting the needle pitch and warp feeding volume of the warp knitting machine, the porosity of the fabric can be optimized, so that it can enhance breathability while maintaining elasticity.

In addition, matte treatment usually involves the application of matting agents or special spinning processes, which require careful operation to avoid clogging of fiber pores and affecting the quick-drying performance. Advanced finishing techniques, such as low-temperature plasma treatment, can enhance surface hydrophilicity without damaging fiber elasticity, thereby improving overall wear comfort.

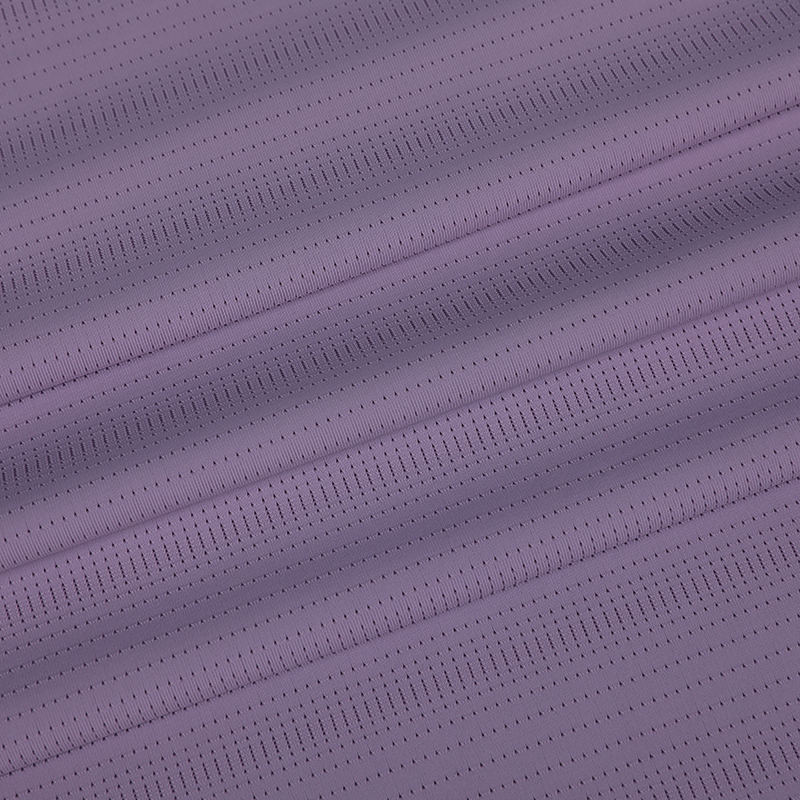

Future development trends of Tricot fabric in the swimsuit market

As consumers' demand for functional clothing grows, Tricot fabric's application in the swimsuit field will continue to deepen. In the future, the application of smart fibers may further promote breakthroughs in elasticity and quick-drying performance. For example, temperature-sensitive fibers can automatically adjust breathability based on ambient humidity, while new elastomeric materials may provide a more lasting rebound performance.

English

English 中文简体

中文简体 Español

Español 日本語

日本語