Submit feedback

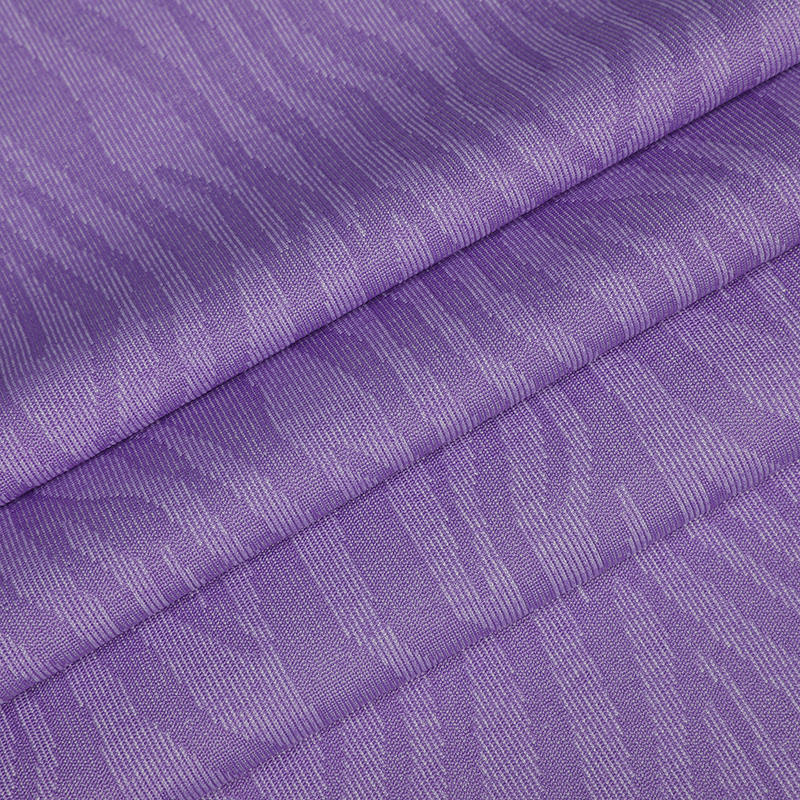

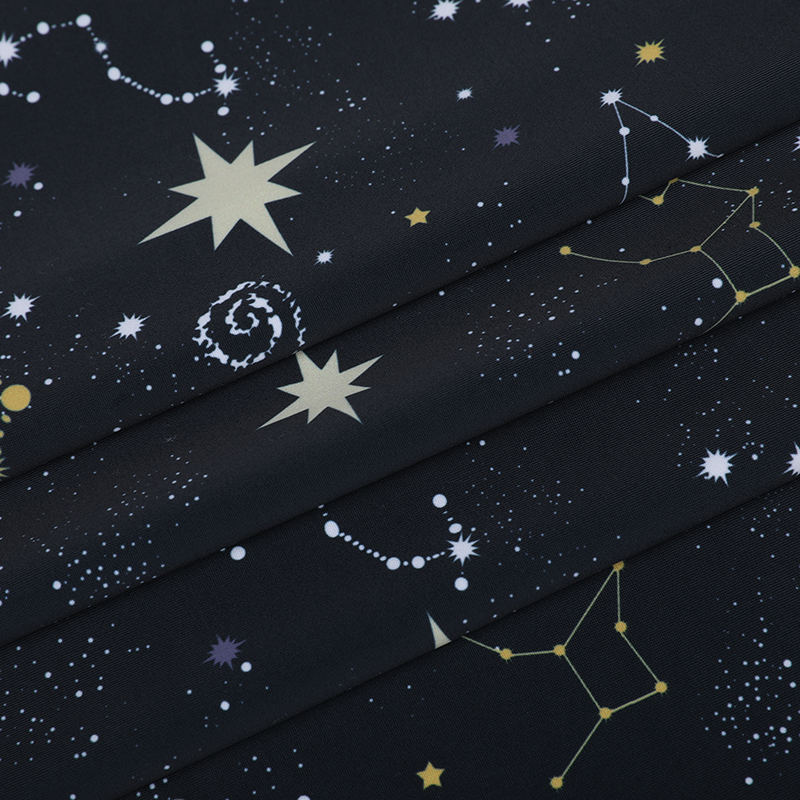

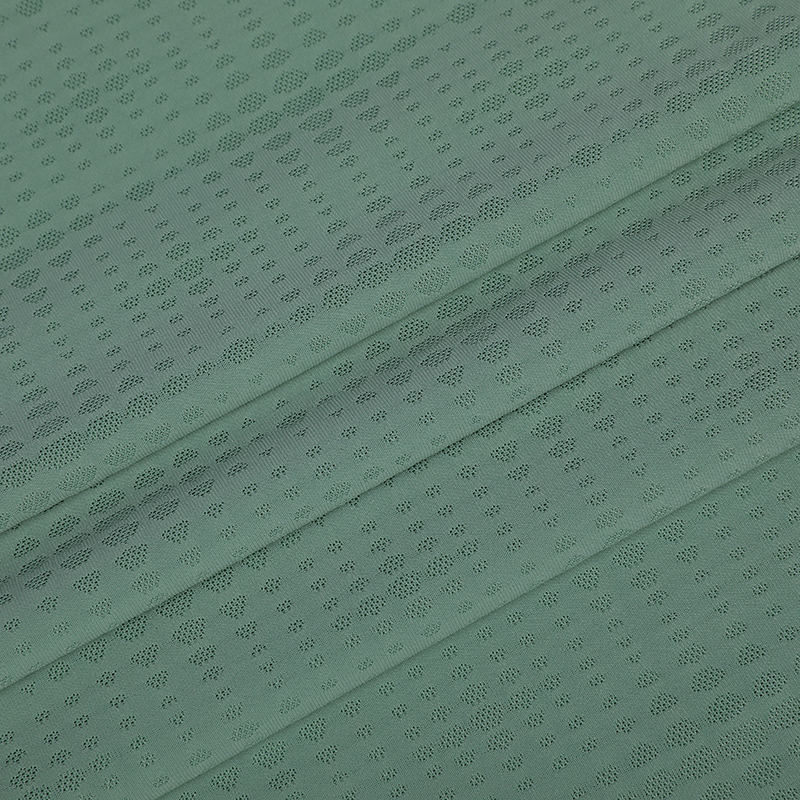

ATY Imitation Cotton Yarn Imitation Cotton Jersey: Structural Empowerment and Process Innovation

2025-07-04

ATY imitation cotton yarn imitation cotton jersey shows unique advantages in the field of fabric performance, and its core comes from the complex interweaving form in the yarn core structure. The exquisite combination of entanglement, twisting and network gives the yarn mechanical properties. This special structure is like a precise mechanical network, which enables the internal parts of the yarn to work closely together and effectively disperse stress when subjected to external forces. When faced with the stretching and friction of daily wear, or the mechanical forces during washing, the yarn is not easy to break due to its high strength characteristics, which provides a solid guarantee for the durability of the imitation cotton jersey and ensures that the clothing can maintain structural integrity during frequent use.

Excellent performance ensures stable quality

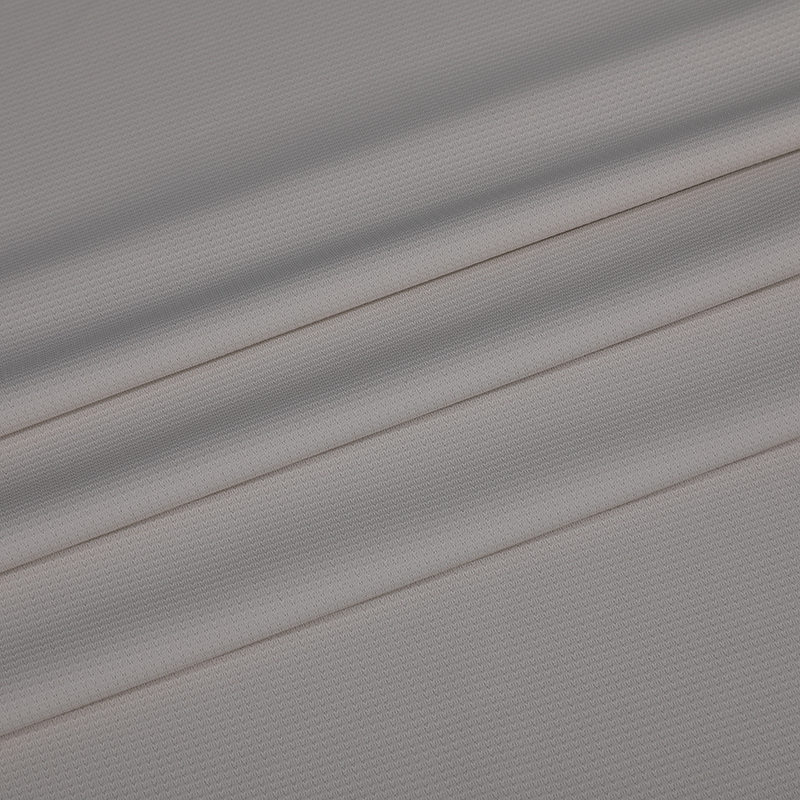

From the overall performance point of view, the imitation cotton jersey made of ATY imitation cotton yarn not only has high strength, but also has stability. In the actual wearing process, the clothes will experience various environmental factors and external forces, and the imitation cotton jersey always maintains a good shape due to its stable performance. Whether it is thermal expansion and contraction in a high temperature environment or chemical reactions after contact with different chemical detergents, its structure and performance can remain relatively stable, and it is not easy to deform or fade. This stability allows consumers to wear clothes without worrying about rapid damage due to external factors, and can maintain a good appearance and texture for a long time, greatly improving the wearing experience.

Innovative technology simplifies the production process

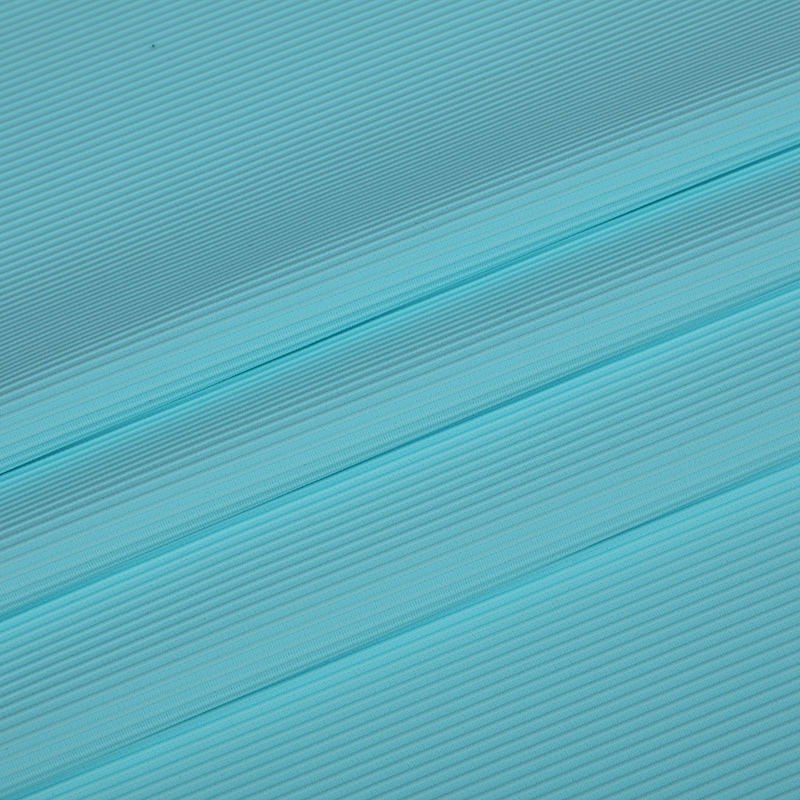

In the dyeing and finishing process, ATY imitation cotton yarn imitation cotton jersey shows significant process advantages. Different from traditional staple yarns that require cumbersome twisting, sizing and desizing, ATY imitation cotton yarn simplifies the process with its special structure. The twisting, sizing and desizing process is not only time-consuming and labor-intensive, but also increases production costs and may have a certain impact on yarn performance. ATY imitation cotton yarn imitation cotton jersey does not require these complex processes, reducing energy consumption and material waste in the production process, and effectively reducing production costs. In addition, since the interference of additional treatment on yarn performance is avoided, the fabric can better retain its original strength and stability after dyeing and finishing, ensuring that product quality is not affected.

Quality assurance extends the service life

Thanks to the special structure of ATY imitation cotton yarn and the simplified dyeing and finishing process, imitation cotton jersey can still maintain a good appearance and texture during long-term use. Even after multiple washings and wearings, its color is still bright, and the surface of the fabric is not easy to pilling or wrinkling. This long-term quality assurance significantly extends the service life of clothing made of imitation cotton jersey. For consumers, buying such clothing can not only provide a comfortable wearing experience, but also reduce the cost and energy of frequent replacement due to clothing damage. For manufacturers, the improvement of product quality helps to enhance brand competitiveness, win consumer trust, and thus occupy a more advantageous position in the market.

Broad prospects industry change

ATY imitation cotton yarn imitation cotton jersey has shown broad development prospects in the textile industry with its comprehensive advantages in strength, stability, production technology and quality maintenance. Its unique performance meets the market demand for high-quality fabrics, and has great application potential in both the clothing field and home textiles. As consumers' requirements for product quality and environmental protection continue to increase, this fabric with performance and more environmentally friendly and efficient production process is expected to technological innovation and product upgrades in the textile industry, inject new vitality into the development of the industry, and promote the textile industry to move towards a higher quality and more sustainable direction.

English

English 中文简体

中文简体 Español

Español 日本語

日本語