Submit feedback

Warp Knitting Fabric: Unveiling Innovation and Versatility in Textile Industry

2025-06-05

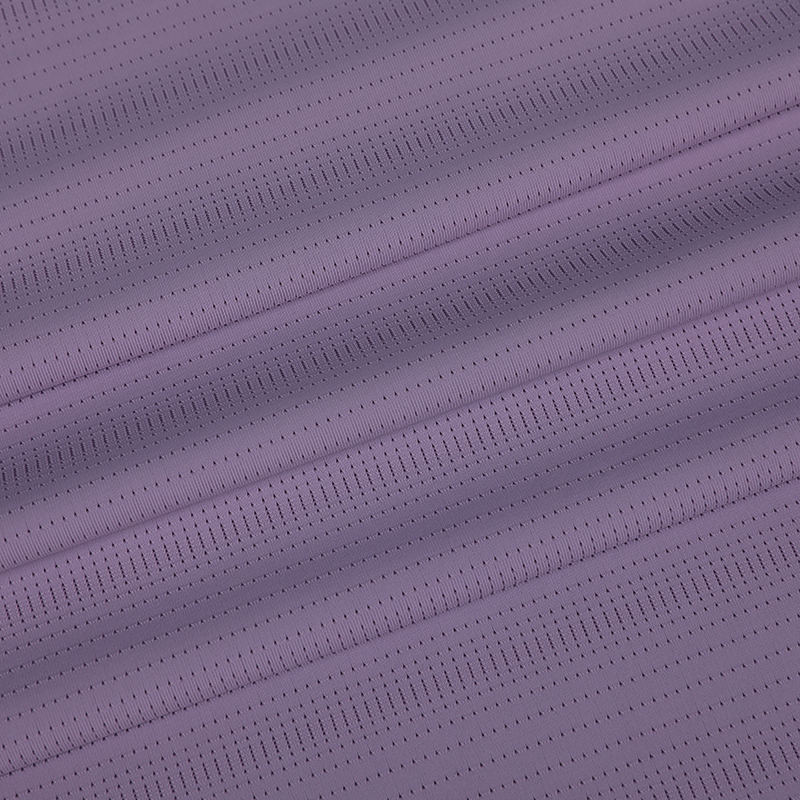

In the dynamic and ever - evolving world of textiles, warp knitting fabric has emerged as a game - changer, revolutionizing the way fabrics are crafted and utilized across a wide range of industries. This unique knitting technique offers distinct advantages that have propelled its popularity and opened up new possibilities in textile manufacturing.

Technological Advancements in Warp Knitting Fabric Production

The production of warp knitting fabric has witnessed remarkable technological advancements in recent years. Modern warp knitting machines are equipped with state - of - the - art computer - controlled systems. These systems enable precise control over every aspect of the knitting process, from the tension of the yarns to the pattern formation. For example, advanced electronic jacquard devices integrated into warp knitting machines can create highly intricate and detailed designs, allowing manufacturers to produce fabrics with complex motifs and textures that were previously difficult to achieve.

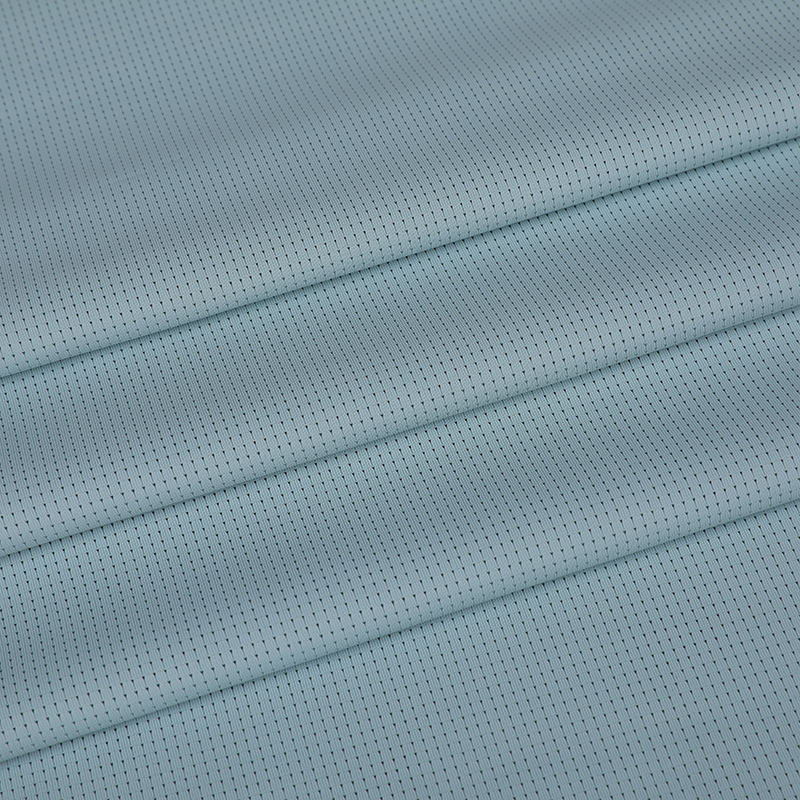

Another significant development is in the area of yarn feeding mechanisms. Newer machines feature multiple yarn - feeding systems that can handle a variety of different yarns simultaneously. This flexibility allows for the creation of warp knitting fabrics with a combination of different fiber types, such as blending natural fibers like cotton and silk with synthetic fibers like polyester and nylon. The result is a fabric that combines the best properties of each fiber, offering enhanced strength, durability, breathability, and comfort.

Moreover, the use of 3D knitting technology in warp knitting has brought about a paradigm shift. 3D warp knitting fabric can be produced in a single - piece construction, eliminating the need for additional sewing or assembly processes. This not only reduces production time and costs but also enables the creation of complex three - dimensional shapes, which are highly sought after in industries such as sportswear and automotive interiors.

Diverse Applications of Warp Knitting Fabric

Warp knitting fabric's versatility has led to its extensive use across numerous industries. In the fashion industry, it has become a staple for creating trendy and functional garments. For swimwear and underwear, warp knitting fabric's stretchability and form - fitting nature make it an ideal choice. It can hug the body's contours, providing a flattering fit while also offering support. The fabric's quick - drying properties are also highly valued in swimwear, ensuring comfort even after getting wet.

In the sportswear sector, warp knitting fabric is widely used for activewear. Its ability to wick away moisture from the body helps keep athletes dry and comfortable during intense physical activities. Additionally, the fabric's durability and resistance to abrasion make it suitable for high - impact sports. Compression garments made from warp knitting fabric are also popular, as they can improve blood circulation and reduce muscle fatigue.

Beyond fashion, warp knitting fabric finds applications in home textiles. It is used for curtains, upholstery, and bedding. In curtains, the fabric's light - filtering and privacy - providing properties, combined with its aesthetic appeal, make it a preferred choice. For upholstery, warp knitting fabric offers good resistance to wear and tear, ensuring that furniture remains looking good for longer. In the automotive industry, warp knitting fabric is used for car seats, headliners, and door panels. Its ability to provide comfort, noise insulation, and a high - quality appearance makes it an essential material in vehicle interiors.

Market Trends and Future Prospects

The market for warp knitting fabric is experiencing significant growth, driven by several trends. The increasing demand for sustainable textiles is having a major impact. Manufacturers are now focusing on using eco - friendly yarns, such as recycled fibers, in the production of warp knitting fabric. Additionally, efforts are being made to reduce the environmental impact of the production process, through initiatives like water conservation and energy - efficient manufacturing.

Another trend is the growing popularity of customized and personalized products. Consumers are looking for unique fabrics that reflect their individual styles. Warp knitting technology's ability to create a wide variety of designs and textures makes it well - positioned to meet this demand. Manufacturers are offering more customization options, allowing customers to choose from a range of colors, patterns, and fabric properties.

Looking ahead, the future of warp knitting fabric is filled with promise. As technology continues to advance, we can expect to see even more innovative applications and improvements in fabric performance. The integration of smart materials and technologies into warp knitting fabric, such as incorporating sensors for health monitoring in sportswear or self - cleaning properties in home textiles, is likely to be a key area of development. With its versatility, technological potential, and growing market demand, warp knitting fabric is set to play an increasingly important role in the textile industry for years to come.

English

English 中文简体

中文简体 Español

Español 日本語

日本語