Submit feedback

Tricot Fabric Redefines Lightweight and Breathable Textiles

2025-08-28

In the current textile industry, the demand for materials that combine durability, comfort, and performance continues to rise. Among the numerous warp-knitted fabrics, tricot fabric has gained distinctive attention, primarily because of its lightweight structure and exceptional breathability. This single feature has not only shaped its wide adoption in apparel and technical textiles but has also redefined the standards for fabrics that balance softness and resilience.

The Structural Advantage of Warp Knitting

Unlike woven materials, warp knit tricot fabric is constructed through a continuous interlooping of yarns along the warp direction. This creates a smooth, fine surface on one side and a slightly textured reverse side. The warp-knitted design inherently reduces fabric weight while ensuring structural integrity.

The key lies in the balance: the loops are tightly interlocked, providing durability without the density commonly found in woven textiles. As a result, tricot materials exhibit an open, breathable matrix that allows for efficient air circulation. This is the engineering foundation behind their lightweight comfort, a quality particularly valued in sportswear, lingerie, and swimwear.

Lightweight and Breathability as Core Differentiators

The lightweight character of tricot fabric does not compromise strength. On the contrary, its resilient elasticity makes it ideal for intensive use in performance garments. The fabric achieves a dual effect: reduced bulkiness for wearer comfort and increased ventilation to regulate body temperature.

When combined with fibers such as polyester or nylon, tricot fabrics can be engineered to achieve specific functional attributes. The polyester tricot fabric enhances moisture management, while nylon tricot fabric is often praised for softness and abrasion resistance. Both directions share the same principle—maintaining breathability without sacrificing flexibility.

Applications Enhanced by Lightweight Structure

Breathability is not merely a comfort indicator; it also defines the functional potential of a fabric. In sectors such as swimwear, lightweight fabrics help maintain hydrodynamics while ensuring quick drying. In lingerie, breathable tricot fabrics ensure all-day wearability without discomfort. The combination of soft tricot fabric and quick-dry tricot fabric represents a powerful balance that directly responds to consumer needs.

To illustrate the versatility of this feature, the following table highlights different tricot fabric variants with a focus on breathability and lightweight characteristics:

| Fabric Type | Composition | Core Feature | Application Focus |

|---|---|---|---|

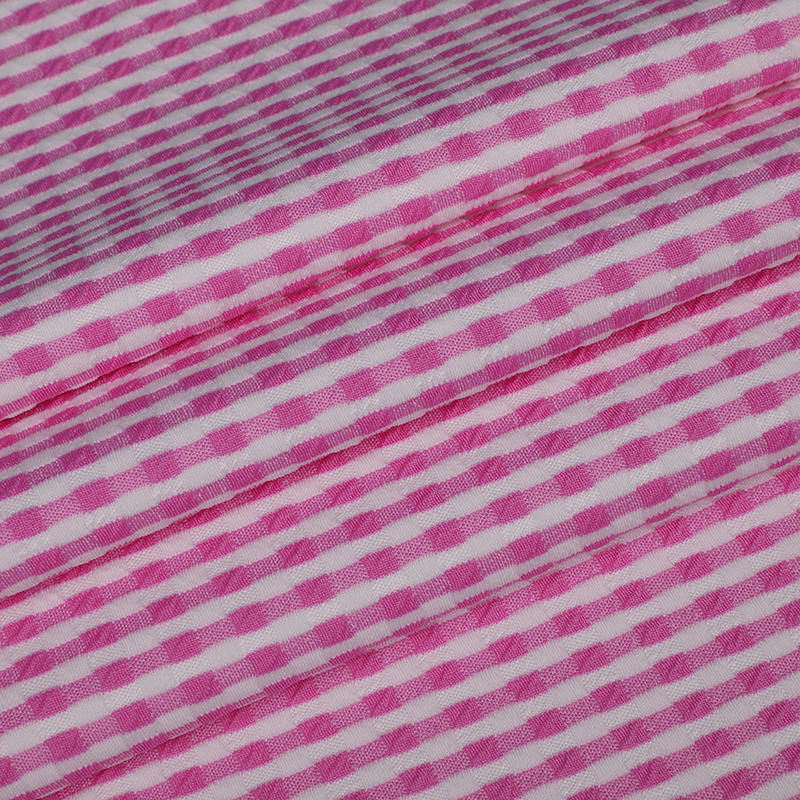

| Polyester tricot fabric | Polyester | Lightweight, moisture-wicking | Sportswear, linings |

| Nylon tricot fabric | Nylon | Softness, abrasion resistance | Lingerie, intimate apparel |

| Stretch tricot fabric | Nylon/Spandex blend | Elastic recovery, breathable | Activewear, performance wear |

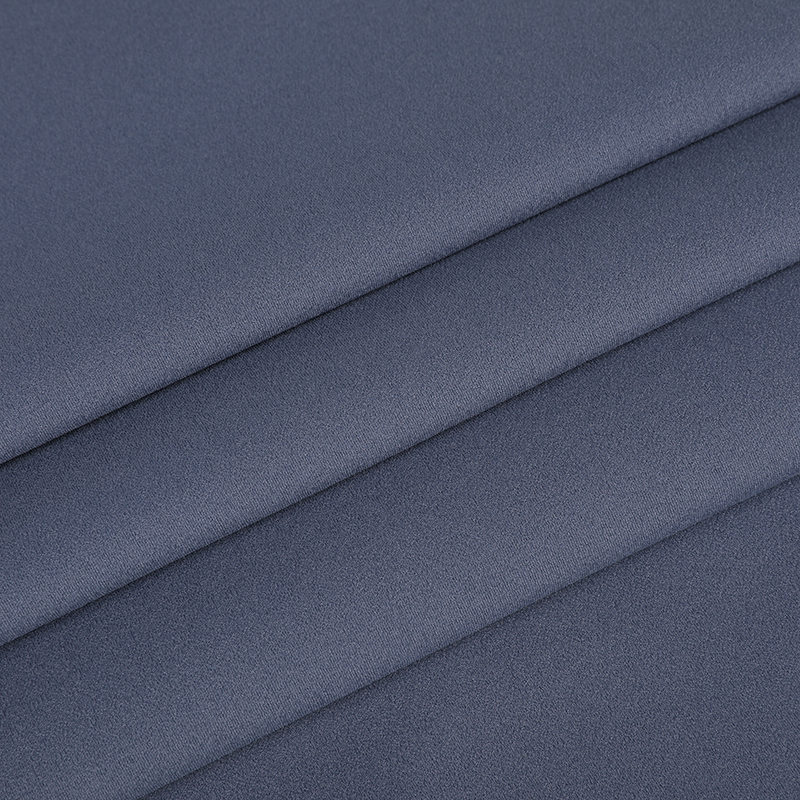

| Polyester ammonia matte swimsuit fabric | Polyester + Spandex | Matte surface, quick-dry, lightweight | Swimwear, beachwear |

Integration with Modern Consumer Needs

As markets shift toward performance-oriented apparel, tricot knit fabric provides manufacturers with a reliable option. Consumers increasingly expect garments that feel natural on the skin, regulate moisture, and allow for prolonged activity without discomfort. The lightweight tricot fabric meets these expectations through a balance of softness, elasticity, and airflow.

In the design of polyester ammonia matte swimsuit fabric, the matte surface reduces glare while the lightweight warp-knitted base allows for swift water release. This combination directly responds to consumer expectations for both function and aesthetic refinement.

Sustainability and Lightweight Efficiency

Another dimension that reinforces the relevance of lightweight tricot fabrics is sustainability. Less yarn mass in production translates to reduced resource consumption without compromising textile stability. Moreover, modern tricot fabrics are increasingly being manufactured with recycled polyester, maintaining the same lightweight breathability while reducing environmental impact.

The lightweight design also contributes to transportation efficiency—lower fabric weight reduces shipping volume, offering additional environmental and economic benefits for global supply chains.

Technical Advantages Driving Industry Adoption

- Durability without weight penalty – Warp knitting ensures stability and stretch without heavy density.

- Elastic recovery – The fabric can stretch and return to its shape, ideal for active applications.

- Quick drying – The open loop construction accelerates evaporation of moisture.

- Skin-friendly softness – Despite its structural resilience, tricot maintains a smooth and comfortable touch.

- Design flexibility – Easily adaptable for sportswear, lingerie, upholstery, and swimwear.

From Sportswear to Technical Fields

The role of lightweight tricot materials is expected to expand beyond apparel. In automotive linings, upholstery, and industrial applications, the fabric’s lightweight strength and breathability are equally valued. Whether as lining fabric for footwear or as a warp knitted tricot production element in upholstery, the lightweight foundation ensures adaptability.

In the long term, advancements in fiber blends and warp knitted tricot production will continue to refine how fabrics balance comfort and durability. By focusing on breathability and lightness, tricot materials are positioned to remain central in performance-oriented textiles.

English

English 中文简体

中文简体 Español

Español 日本語

日本語