Submit feedback

The Science Behind Durable and Stretchable Swimwear Fabrics

2025-10-09

Introduction

Swimwear fabric plays a pivotal role in modern apparel, combining style, comfort, and performance. While aesthetics and fit are essential, durability and stretchability are the defining features that determine long-term satisfaction. Advances in textile technology have allowed swimwear fabrics to not only maintain their shape over repeated use but also provide resistance to environmental factors such as chlorine, saltwater, and UV exposure. Among these innovations, the integration of materials like organic cotton and high-performance synthetic fibers has become increasingly prominent, balancing sustainability with functional performance.

Understanding Durability in Swimwear Fabrics

Durability in swimwear fabric refers to its ability to resist wear, tear, and degradation over time. Several factors influence durability: fiber type, fabric construction, and finishing treatments.

Key Components of Durable Swimwear Fabric

Synthetic Fibers: Polyamide (nylon) and polyester are widely used due to their high tensile strength and resistance to abrasion. These fibers provide structural integrity, ensuring that swimwear retains its shape after repeated stretches.

Spandex (Elastane): Known for its exceptional stretch and recovery properties, spandex enhances comfort and mobility without compromising durability.

Organic Cotton Blends: Incorporating organic cotton improves comfort and breathability. When combined with spandex, organic cotton offers a sustainable option that remains soft while maintaining resilience.

| Fiber Type | Durability Factor | Advantages | Environmental Consideration |

|---|---|---|---|

| Polyamide | High abrasion resistance | Retains shape, fast-drying | Non-biodegradable, recyclable |

| Polyester | UV and chlorine resistant | Maintains color, long-lasting | Low water consumption in production when recycled |

| Spandex | High elasticity | Allows stretch and recovery | Non-biodegradable, small percentage used improves efficiency |

| Organic Cotton | Moderate durability | Soft, breathable, skin-friendly | Sustainable, biodegradable |

This table illustrates how combining fibers can optimize swimwear fabric, balancing durability, comfort, and sustainability.

The Role of Stretchability in Swimwear Performance

Stretchability is crucial for swimwear fabric, ensuring comfort and freedom of movement. A fabric that stretches effectively adapts to the body, providing support without constriction. The stretch performance of swimwear fabric depends primarily on fiber elasticity, knit or weave construction, and finishing treatments.

How Stretch Works

Swimwear fabric often combines elastic fibers with resilient synthetics. The elasticity allows the fabric to extend under tension and return to its original shape without deformation. Key considerations include:

Stretch Recovery: The ability of fabric to return to its original shape after stretching prevents sagging and bagging over time.

Directional Stretch: Four-way stretch fabrics provide flexibility in multiple directions, ideal for competitive swimwear and active lifestyles.

Fabric Density: Denser knits may reduce overall stretch but improve durability; looser knits increase elasticity but require reinforcement.

| Property | Importance for Swimwear | Optimal Range |

|---|---|---|

| Stretch (%) | Comfort and fit | 15–30% for standard swimwear |

| Recovery (%) | Shape retention | ≥ 90% |

| Tensile Strength | Resistance to tearing | High |

| Fabric Weight (gsm) | Balance of comfort & durability | 180–250 |

This data-driven approach demonstrates how manufacturers balance stretch and durability to create functional swimwear fabrics.

Material Innovations in Durable and Stretchable Swimwear

Innovations in swimwear fabric have focused on enhancing both durability and stretchability while maintaining sustainability.

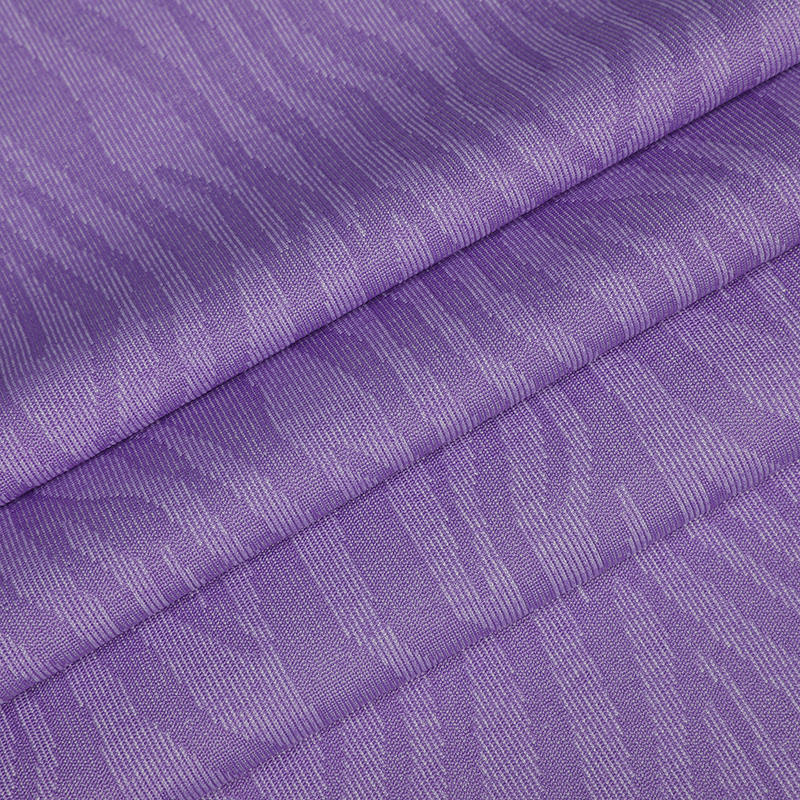

Organic Cotton Integration

Organic cotton is increasingly incorporated into swimwear blends for its soft feel and eco-friendly production. While cotton alone lacks the elasticity required for swimwear, blending it with spandex or polyester creates a hybrid fabric that is soft, breathable, and durable. Key advantages include:

Skin Comfort: Ideal for sensitive skin and prolonged wear.

Moisture Management: Organic cotton absorbs moisture, while spandex layers aid quick drying.

Sustainability: Reduced pesticide use and biodegradable fibers align with consumer demand for eco-conscious products.

Coating and Finishing Techniques

Durable swimwear fabrics often undergo chemical or mechanical treatments to enhance performance:

Chlorine Resistance: Protective coatings minimize fiber degradation in pools.

UV Protection: Special treatments prevent color fading and fiber weakening from sun exposure.

Water Repellency: Advanced finishes allow water to bead off, enhancing comfort and drying speed.

| Treatment Type | Purpose | Effectiveness on Durability | Effectiveness on Stretch |

|---|---|---|---|

| Chlorine-resistant coating | Reduce fiber breakdown | High | Moderate |

| UV-protective finish | Prevent color fading | Moderate | High |

| Water-repellent finish | Fast drying & comfort | Low | High |

These treatments exemplify how science-driven approaches can improve swimwear fabric performance without compromising comfort or flexibility.

Testing and Quality Assurance

Durable and stretchable swimwear fabric must undergo rigorous testing to ensure performance under real-world conditions. Standard tests include:

Tensile Strength Testing: Measures the force required to stretch and break the fabric.

Stretch Recovery Testing: Evaluates the fabric’s ability to regain shape after repeated stretching.

Chlorine and UV Exposure Tests: Assess long-term resistance to environmental stressors.

| Test Type | Standard Method | Expected Outcome |

|---|---|---|

| Tensile Strength | ISO 13934-1 | No tearing under specified load |

| Stretch Recovery | ASTM D2594 | ≥ 90% recovery after 50 cycles |

| Chlorine Resistance | Repeated pool exposure | Minimal fiber degradation |

| UV Resistance | Xenon lamp exposure | Color retention ≥ 80% |

Quality assurance ensures that swimwear fabrics meet both consumer expectations and industry standards.

Future Trends in Swimwear Fabric

The swimwear fabric industry is evolving with new consumer demands for performance, comfort, and sustainability. Future innovations are likely to focus on:

Bio-based Stretch Fibers: Combining renewable resources with high elasticity.

Smart Fabrics: Integrating moisture management or UV-sensing technologies.

Enhanced Recycling: Fabrics designed for circular use without compromising durability or stretch.

Consumers increasingly prioritize eco-conscious materials, such as organic cotton blends, while maintaining high-performance standards in elasticity and durability. The intersection of material science and sustainable production defines the next generation of swimwear fabrics.

Conclusion

The science behind durable and stretchable swimwear fabrics combines material innovation, construction techniques, and protective treatments to deliver comfort, performance, and longevity. Incorporating fibers like spandex, polyester, and organic cotton allows swimwear fabric to achieve a balance of stretch, recovery, and durability. Testing standards ensure consistent quality, while sustainability initiatives guide the future of eco-friendly production.

English

English 中文简体

中文简体 Español

Español 日本語

日本語