Submit feedback

How Do Warp Knitting Fabrics Compare to Weft Knitting in Terms of Strength and Stretch?

2026-01-01

Knitted fabrics have revolutionized the textile industry due to their versatility, durability, and comfort. Two of the popular knitting methods used to create fabrics are warp knitting and weft knitting. Both techniques offer distinct benefits, but when it comes to strength and stretch, the differences become particularly notable.

Introduction to Knitting Techniques

Warp Knitting:

Warp knitting is a type of knitting where the yarns run vertically along the fabric. In this technique, the yarns are arranged in parallel, and each needle is responsible for creating a vertical column of loops. The process is typically done using machines with multiple needles working in a coordinated fashion, allowing for the production of complex patterns with high precision.

Weft Knitting:

Weft knitting, on the other hand, involves a horizontal process where the yarns run across the fabric, forming loops that interlock with the adjacent loops in the same row. This method is typically used for creating fabrics like t-shirts, sweaters, and socks, often employing circular or flatbed knitting machines.

Both methods use similar principles of interlocking loops, but the direction of the yarns and the machines used create a significant difference in the final fabric’s properties.

Strength of Warp Knitting vs. Weft Knitting

Warp Knitting Fabrics:

One of the key advantages of warp knitting fabrics is their high tensile strength. This strength is derived from the vertical arrangement of the yarns, which provides a greater resistance to pulling and tearing compared to weft-knitted fabrics. The use of multiple yarns in the warp knitting process contributes to the overall durability of the fabric.

Additionally, warp knitting fabrics are known for their dimensional stability, meaning they are less prone to stretching or distorting over time. This characteristic makes warp-knitted fabrics ideal for applications that require heavy-duty performance, such as industrial textiles, automotive fabrics, and sportswear.

Key Strengths of Warp Knitting:

- Higher tensile strength

- Increased durability and resistance to wear

- Better dimensional stability, preventing stretching or sagging

Weft Knitting Fabrics:

Weft knitting fabrics, while generally weaker than warp-knitted fabrics in terms of tensile strength, offer more flexibility and stretchability. The horizontal structure allows for more natural give and stretch, which is why weft knitting is often used in applications that require elasticity, such as activewear or undergarments.

While the stretchability of weft knitting fabrics can be an advantage in specific applications, this method does not provide the same level of strength or resistance to wear and tear that warp knitting offers. As a result, weft knitting may not be as suitable for industrial or heavy-duty applications.

Key Strengths of Weft Knitting:

- Greater elasticity and stretchability

- More comfort for close-fitting garments

- Flexibility in terms of design patterns

Stretchability: Comparing Warp and Weft Knitting

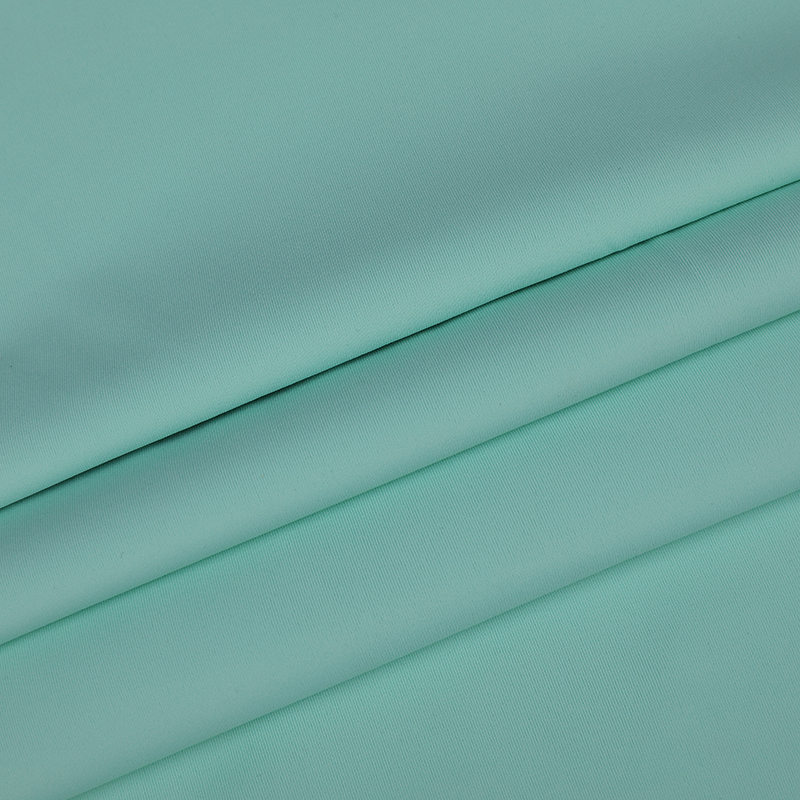

Warp Knitting Fabrics:

Warp knitting fabrics tend to have less inherent stretch compared to weft knitting fabrics. This is due to the vertical alignment of the yarns, which are tightly interlocked, offering limited flexibility. However, some warp-knitted fabrics, such as those incorporating elastane or spandex fibers, can still achieve a moderate degree of stretch, although it will generally not match the stretchability of weft knitting.

The limited stretch of warp-knitted fabrics does not compromise their performance in cases. In fact, the lack of excessive stretch can be beneficial in applications where stability and structure are more important than flexibility. This includes fabrics used for outdoor gear, heavy-duty uniforms, and some types of medical textiles.

Key Benefits of Warp Knitting’s Stretchability:

- Controlled and limited stretch, providing stability

- Ideal for applications requiring a firm structure

- Ability to integrate stretch fibers like spandex for added comfort

Weft Knitting Fabrics:

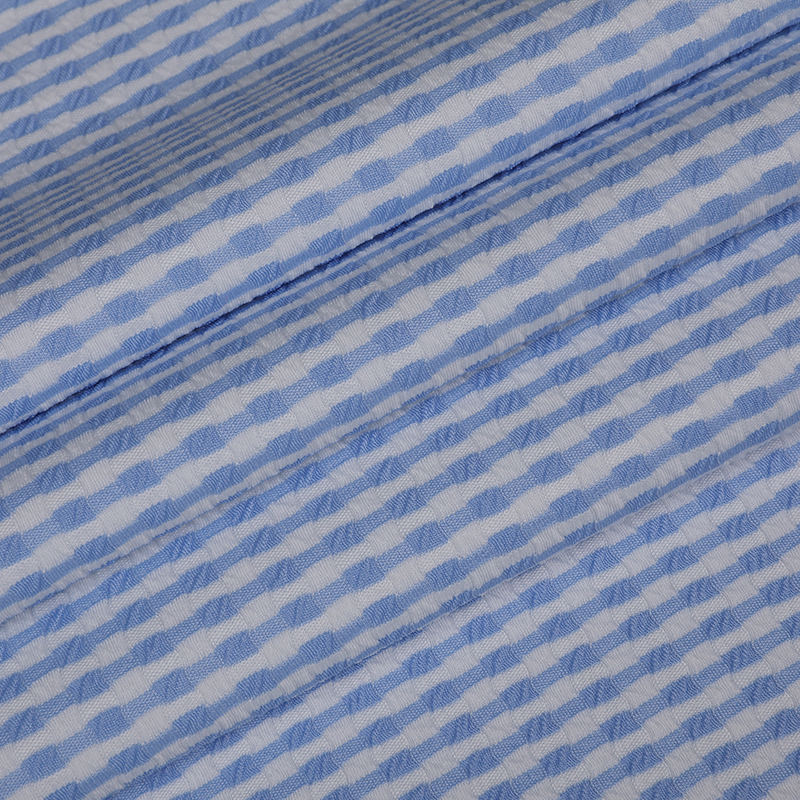

Weft knitting fabrics are known for their exceptional stretch, which is one of their notable features. The loops created in the horizontal direction provide a natural elasticity that makes the fabric highly flexible. This characteristic is one reason why weft-knitted fabrics are frequently used in the production of stretchy garments such as leggings, sportswear, and t-shirts.

Because the fabric stretches more easily, it is better suited for comfort-driven applications where the garment needs to fit tightly or move with the body. However, the high level of stretch can sagging or distortion over time, especially in the case of low-quality yarns or improper finishing processes.

Key Benefits of Weft Knitting’s Stretchability:

- High elasticity and comfort

- Excellent for form-fitting clothing and activewear

- Ability to mold to the body for a more flexible fit

Applications: Where Do Warp and Weft Knitting Excel?

Warp Knitting Applications:

Due to its strength, dimensional stability, and resistance to stretching, warp knitting is commonly used in industries that require high-performance fabrics. Some of the notable applications include:

- Sportswear: Fabrics used for compression garments, cycling jerseys, and swimsuits.

- Automotive Textiles: Car seat covers and upholstery that need to withstand wear and tear.

- Medical Textiles: Bandages, braces, and other medical products that require durability.

- Industrial Textiles: Fabrics for protective clothing and equipment.

Weft Knitting Applications:

Weft knitting is primarily used for garments that benefit from elasticity and flexibility. It is popular in the fashion and textile industries for products like:

- Activewear: Running tights, gym wear, and yoga pants.

- Casualwear: T-shirts, sweatshirts, and socks.

- Underwear: Stretch fabrics that mold to the body for comfort.

Comparative Strength and Stretch Table

| Characteristic | Warp Knitting Fabric | Weft Knitting Fabric |

|---|---|---|

| Strength | High tensile strength, durable | Moderate strength, less durable |

| Stretchability | Limited stretch | High elasticity, more stretch |

| Dimensional Stability | Excellent, less prone to distortion | Moderate, may sag over time |

| Comfort | Less flexible, more structured | Highly comfortable, stretchy |

| Applications | Heavy-duty, industrial, medical | Fashion, activewear, casualwear |

Conclusion

Warp and weft knitting fabrics both offer unique advantages depending on the intended application. Warp knitting excels in strength and durability, making it ideal for industrial and performance-driven textiles. In contrast, weft knitting shines in stretchability and comfort, making it for flexible and close-fitting garments.

Understanding these differences is crucial when selecting the right fabric for your needs. While warp-knitted fabrics are ideal for applications requiring strength and structure, weft-knitted fabrics are for situations where flexibility and comfort are paramount.

FAQ

1. Which knitting method is stronger, warp or weft knitting?

Warp knitting is generally stronger than weft knitting due to the vertical yarn arrangement, offering greater resistance to pulling and tearing.

2. What type of garments are made from warp knitting fabrics?

Warp knitting fabrics are suitable for heavy-duty garments such as sportswear, automotive textiles, and medical textiles.

3. Can warp knitting fabrics stretch?

While warp knitting fabrics have limited stretch, they can be engineered with stretch fibers for added flexibility, although they do not match the stretchiness of weft knitting.

4. Why is weft knitting preferred for casualwear?

Weft knitting offers high stretchability and comfort, making it ideal for garments like t-shirts, leggings, and activewear.

5. Are there any downsides to using weft-knitted fabrics?

Weft-knitted fabrics, while highly flexible, can experience sagging or distortion over time, especially if the yarns used are of lower quality.

English

English 中文简体

中文简体 Español

Español 日本語

日本語