Submit feedback

Exploring the Flexibility of Weft Knitting Fabric in Sportswear Manufacturing

2025-05-15

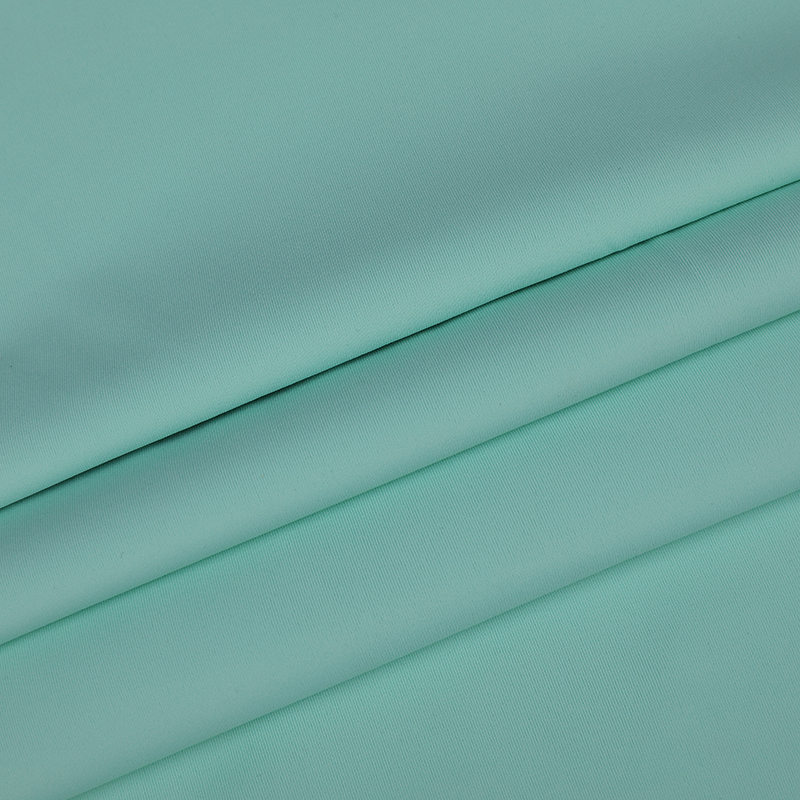

In the dynamic world of sportswear manufacturing, innovation in textile production plays a pivotal role in meeting the evolving demands of consumers. Among the various techniques available, weft knitting fabric has emerged as a preferred choice for producing high-performance materials tailored to active lifestyles. Known for its flexibility, comfort, and versatility, weft knitting fabric offers unparalleled advantages that cater to the unique requirements of sportswear.

What is Weft Knitting Fabric?

Weft knitting fabric is created through a process where a single yarn is looped horizontally across the material. This technique results in a soft, stretchable, and durable fabric that is also lightweight. Unlike warp knitting, which uses multiple yarns running vertically, weft knitting fabric provides superior elasticity and adaptability in the final product.

These properties have made weft knitting fabric increasingly popular among sportswear manufacturers looking to enhance the functionality and style of their garments.

Key Advantages of Weft Knitting Fabric in Sportswear

1.Enhanced Stretch and Recovery

A defining feature of weft knitting fabric is its exceptional elasticity, making it ideal for sportswear where unrestricted movement is crucial. Whether it’s yoga pants, running gear, or compression garments, the stretch and recovery qualities of weft knitting fabric ensure that the clothing retains its shape and fit even after extensive use.

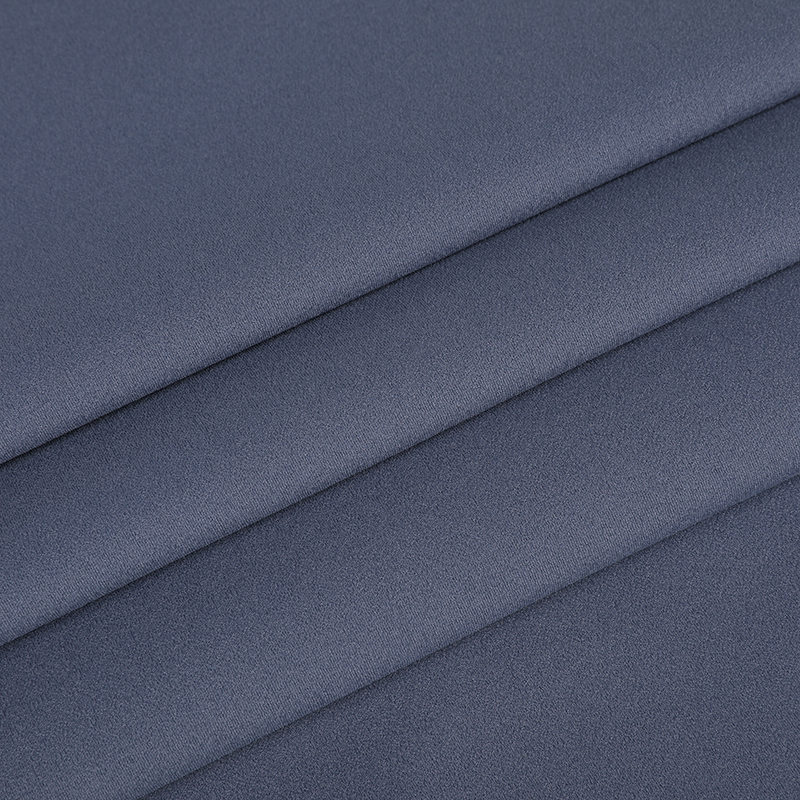

2.Breathability and Moisture Management

The looped structure of weft knitting fabric allows for excellent breathability. This characteristic enables air circulation, effectively wicking moisture away from the skin to keep the wearer cool and dry. This is particularly beneficial for high-intensity sports where regulating body temperature is essential.

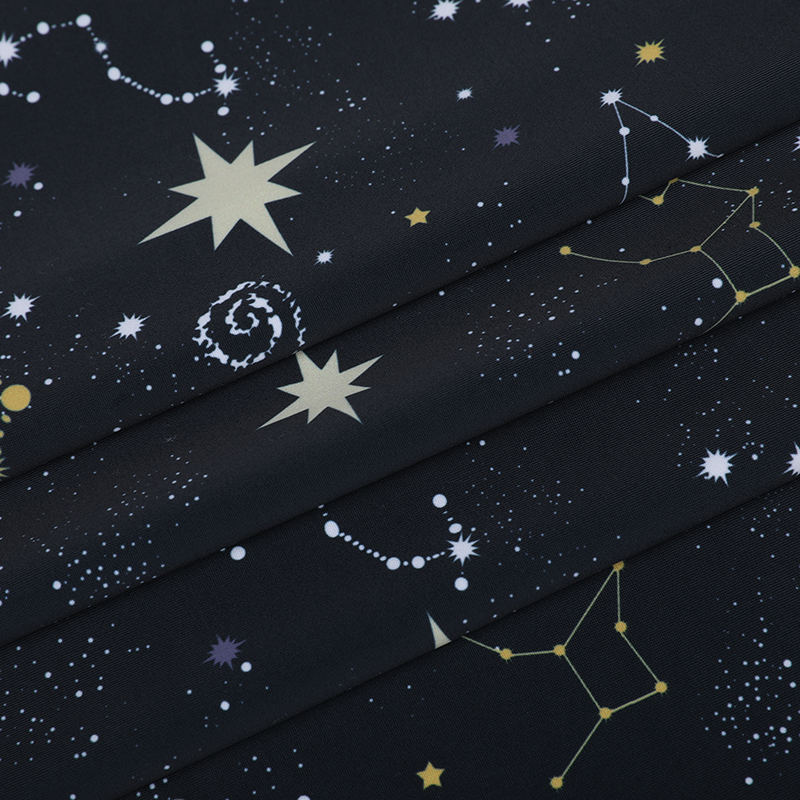

3.Versatile Design Potential

Weft knitting fabric supports intricate patterns, color variations, and textured designs, giving manufacturers the flexibility to create visually appealing sportswear that meets current consumer trends.

4.Lightweight Durability

Despite its lightweight nature, weft knitting fabric is highly durable and resistant to wear and tear. This makes it a perfect material for sportswear that needs to withstand rigorous activity without sacrificing comfort.

5.Sustainability Options

As sustainability becomes a focal point in the fashion industry, weft knitting fabric has proven to be a compatible choice for eco-friendly production. It can be made using recycled or biodegradable yarns, aligning with the growing demand for sustainable sportswear.

Applications of Weft Knitting Fabric in Modern Sportswear

The versatility of weft knitting fabric has paved the way for its use in a wide range of sportswear products:

1.Compression Wear: The elasticity of weft knitting fabric makes it ideal for creating compression garments that support muscles and enhance blood circulation. These features improve performance and recovery for athletes.

2.Seamless Activewear: With advancements in weft knitting technology, seamless garments have become a reality. These garments reduce friction and improve comfort by eliminating bulky seams, making them highly desirable for activewear.

3.Layered Performance Gear: Outdoor sportswear often uses layered weft knitting fabric for thermal insulation and moisture management, ensuring optimal performance in varying weather conditions.

Technological Advancements Driving Innovation

Modern technology has enhanced the production of weft knitting fabric. Programmable machines, automated yarn feeding systems, and high-speed operations have streamlined the process, making it more efficient and precise. These advancements enable the use of innovative materials, including smart textiles that incorporate sensors for monitoring athletic performance.

Additionally, 3D knitting technology has revolutionized the creation of custom-fit sportswear using weft knitting fabric. This approach minimizes waste and aligns with the increasing emphasis on sustainable manufacturing practices.

Challenges and Opportunities

While the advantages of weft knitting fabric are significant, manufacturers face challenges such as maintaining consistency in mass production and managing the cost of advanced machinery. However, the rising consumer demand for high-quality, innovative, and sustainable sportswear presents substantial opportunities for growth.

English

English 中文简体

中文简体 Español

Español 日本語

日本語